Alaskan

0

- Joined

- Jan 29, 2014

- Messages

- 12,025

- Points

- 113

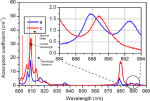

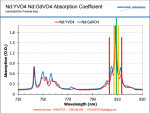

What specification does your 15W C-Mount have. What is the spectral tolerance? I have a Coherent FAP-800 50W that is rated +/- 3nm. This was used in their Coherent Verdi systems and would of been likely to of produced 10-15W of 532nm. If this was +/- 3nm, then I gather your 15W would be acceptable. I can only imagine a 20-30% increase in 1064, for the phase matched 4W. If we presume that 50% of the 808 is converted to 1064, and 60% is converted to 532 then the figures will probably be like:

808 +/- 3nm(15W) --> 1064 (7.5W) --> 532 (4.5W) This is quite an efficient system you would probably expect to have a system efficiency of around 20-30% (3-4.5W)

808.4 (4W) --> 1064 (2.8W) --> 532 (1.68W) The 1064 conversion was 70% in this model.

This is pure speculation. I could look at the graph and try to approximate a true increase in absorption, but it wouldn't be necessary.

Wow, cool info. This 15 watt diode did not come out of anything I know of, is just another one I have. It is new old stock, I have three of them.

Here are the spec's for a non-FAC version of the same diode:

Specifications:

808nm 15W C-Mount Laser Diode

CW output power (W): 15.0

Peak wavelength (nm): 808 +/-5nm

Spectral width (nm): ≤4

Threshold current (A): ≤2.4

Operating current (A): ≤16.0

Slope efficiency (W/A): ≥1.1

Beam divergence θ∥×θ⊥ (deg.): 8/30

Wavelength temperature coefficient (nm/℃): 0.3

Emitting area (μm): 400×1

Last edited: