- Joined

- Jun 25, 2017

- Messages

- 57

- Points

- 0

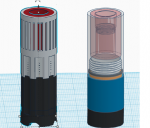

What's to calculate. It's a scalable model. There are a few draw backs to the design imo. I'm not concerned about heatsink in or the typical talk. Let me ask you. Do you have any handheld lasers you have built yourself? With the handhelds I have built I set the module depth in the heatsink based on the focus point of the lens. When the focus adjuster is flush and in contact with the heatsink the focus of the beam would be just outside of infinity focus on the diverging side. That way a small counterclockwise adjustment will bring it into proper focus. If the module isn't set deeper below the face of the heatsink, there will be anywhere from 3mm to 5mm of separation and exposed lens barrel. That would allow an undesirable wobble of the lens and focus adjuster piece. DTR had a 22mm heatsink it was version 2. Look that up. The focus adjuster piece was trick. It's not made anymore. But it would compliment your design to do something similar.

I understand what you are referring to with the focusing length, and that is very smart! But my design will be using the standard 12mm copper diode housing, this way 3.8mm, 5.6mm, and 9mm diodes can all be used along with different diodes and different focus points.