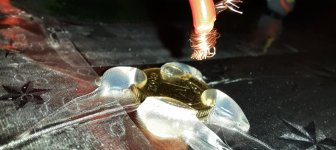

Hello. Recently I was planning to build an air laser based on information from styropyro and plasmachannel films. The 2 capacitors I built here have 4.5nF each. as a laser gap I used aluminum profiles which I sanded with very fine sandpaper. the spark gap is just a wire and a coin. as a source of high voltage I used a standard stun gun module, I tried to change the distance between the laser gap and the spark gap, but it didn't help and I can't make this laser work. I would be very grateful for any advice on what should I do to make this laser work. below I added some pictures of my laser so you can see how it is built. Thank you in advance for your help and best regards

Attachments

-

20210319_210212-min.jpg407 KB · Views: 8

20210319_210212-min.jpg407 KB · Views: 8 -

20210319_210255-min.jpg286.1 KB · Views: 8

20210319_210255-min.jpg286.1 KB · Views: 8 -

20210319_210319-min.jpg443.2 KB · Views: 7

20210319_210319-min.jpg443.2 KB · Views: 7 -

20210319_210354-min.jpg534 KB · Views: 8

20210319_210354-min.jpg534 KB · Views: 8 -

20210319_210404-min.jpg948.6 KB · Views: 8

20210319_210404-min.jpg948.6 KB · Views: 8 -

20210319_210429-min.jpg971.3 KB · Views: 8

20210319_210429-min.jpg971.3 KB · Views: 8 -

20210319_210122-min_optimized.jpg761.4 KB · Views: 9

20210319_210122-min_optimized.jpg761.4 KB · Views: 9 -

20210319_210415_optimized.jpg754.9 KB · Views: 8

20210319_210415_optimized.jpg754.9 KB · Views: 8