I got what you mean RedCowboy. It would have been off by about 1mm.

Anyways I found parts from Thorlabs. It just took a lot of time searching for parts.

Just because the lens pair says 12x12x7mm doesn't mean it will fit in a tube that says for 12mm

optics. It takes a little math here.

Use SL-CHS3 Extended and tapered copper heatsink from survival laser store. It will go inside the 1" tube.

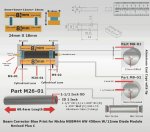

The SM1AD9 has M9 threads and will allow the M9 G2 lens to screw into it using the wrench. The g2 with no focus ring should have a spring under it.

I may have a little overkill with the SM1M30 tube at 3" but it needs 42mm and

2" is 50.8mm so that's not a lot of room to play. The SM1CPL05 will secure it to the S4X host. Small mm difference but the SM1AD9 will center it. The s4x could be brought up a few micro milimeters with electric tape etc.

The SM1AD16 (x2) will hold my cylindrical x6 lens.

Then my SM1CP2M end cap that will be machine drilled.

adaptors to hold lens

10.16mm (thick) x 2 = 20.32mm

adaptor to m9 g2 lens = 10.16mm (thick)

--------------------------------------------

[30.48mm]

Lens tube 76.2mm (length)

-------------------------------------------

Room to play 25.4mm

Updated 9-17-07

SM1A27 'thanks SL'...the s4x thread length is about 4 mm (M26 with 1mm pitch) and the adapter internal threads about 5, SM1AD9 no g2 lens focus ring....it will hold the heatsink down in the 1" tube ...followed by optics/munts...best guess now the 3"length tube is prob more accurate $146.00

I looked for an adapter with smooth internal bore and 1" or SM1 external threads but had no luck finding anything that would directly fit the heatsink to hold it down. You can buy the coupler if you want but probably won't need it.

Mounting the lens pair is a little bit more tricky. I'm going to have to start with the Clear Aperture of the retaining rings. (Note attached photo on fitting a square into a circle). For these from Opt Lasers it's going to need SM19RR Retaining Rings Ø0.64" (Ø16.3 mm). From what I see the thickness of the lens is going to be a problem at 7mm thick. The SM1AD19 allows for 6.1mm thickness max. I may be able to turn 2 of these back to back to mount my lens in 1" tube system from ThorLabs. If this works turning them back to back I will need at least a 1" tube that has a 2" length. (SM1M25)

As for beam expansion, from what I see this is my best and cheapest option after beam correction using the SM1 tube system from thorlabs:

SM1A25 (SM1A25 adapter has external M25.5 x 0.5 threading and internal SM1 (1.035"-40) threading)

laser beam expander offers 1-10X magnification for laser pointers That is a 1-10x beam expander and may be cheaper than building my own. *Will be keeping the expander locked up in a vault so that it never gets aimed up...86 miles to space @6 Watts X 10 my estimates that puts me about 60 miles straight up. Laserbee don't be spraying that at my lens! Ok grab your spray if your really just love me but can't bring yourself to admit it :na:

I got an idea laserbee stand still for a minute while I see if I can bounce my beam off the MLI on a satellite at you

let me know when it hits you.

I'm admitting I'm a little curious about the beam divergence. can you take measurements for me?

My rebuilt S4X is back in action and ready for optics:

A wood print shows a better spot image.

A wood print shows a better spot image.