- Joined

- Sep 20, 2013

- Messages

- 20,284

- Points

- 113

DTR's site shows only pulls for the 44s. I don't believe anyone has brand new diodes for sale. I'm pretty sure they all come out of new blocks before they're put into PJs.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Wouldn't that make them new ? Or am I misunderstanding something ?DTR's site shows only pulls for the 44s. I don't believe anyone has brand new diodes for sale. I'm pretty sure they all come out of new blocks before they're put into PJs.

That's what I thought but wasn't sure, Thanks that's good to know !DTR only sells zero hour NEW pulls or new stock unless he tells you up front that something is from a used machine.

Wouldn't that make them new ? Or am I misunderstanding something ?

By "brand new" I am distinguishing the diodes that have no solder or cut pins from the new pulls. I was getting brand new M140 diodes on eBay back when DTR was getting them as pulls. It cost me a couple $$ more, but I liked having never been soldered on diodes over pulls.

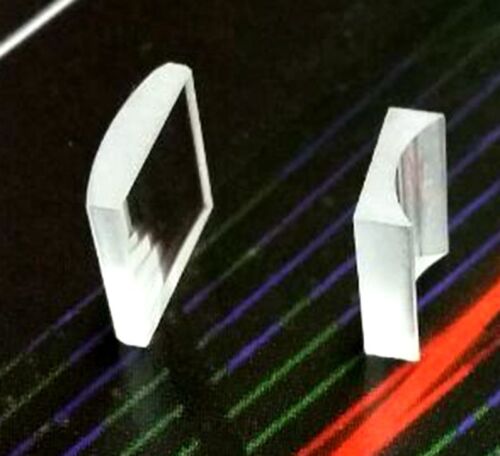

Oh I get what your saying now......I put these together so you would know the difference.

Center to center for the 6X c-lens pair will be right at 35mm but you want to fine tune by hand the final setting before gluing them down and set your concave 1st making sure your rotation and placement left/right is correct by using a target some distance away then when your concave is aligned you set the convex 35mm away and adjust it's rotation and placement.

You lock down your G2 to infinity and make sure your spot which will look like a bar/line is horizontal far field, that is it needs to be perfectly parallel to your optics bed, you do this by adjusting the rotation of your module in your heat sink, then set your concave cyl as close as you reasonably can to your G2 but don't worry if you need to set it a 1/2 an inch away rather than a 1/4 inch away as it's not critical.

I haven't tried the 6X cyl lens pairs on an NDG7475, but it seems like overkill to me. I also have some 2X and 3X lens pairs that might work better for that diode. Just a thought.I've had a set of 6x sitting around for a couple years now that I've been wanting to use with a 7475. I assume you set the focus for infinity. If you did, would you be able to provide some measurements? For example, from the front of the G2 to the back on the first lens of the 6x set. The from the front of the first lens of the set to the back of the second lens.

I don't care about burning. I just want the best beam profile over a long distance.