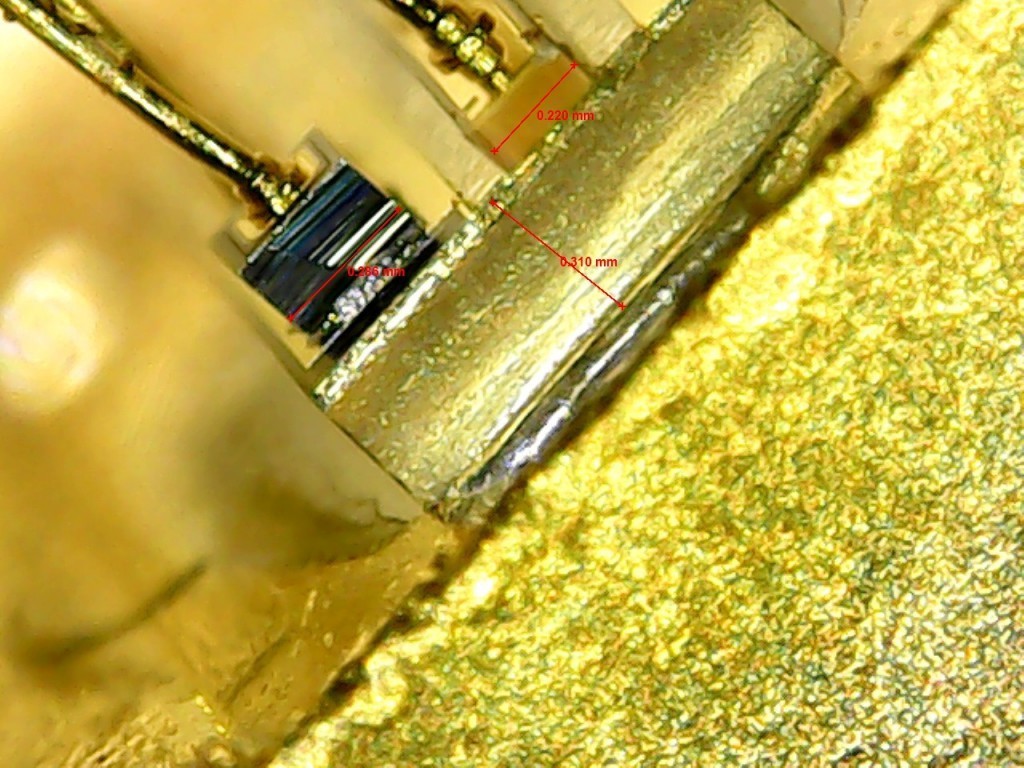

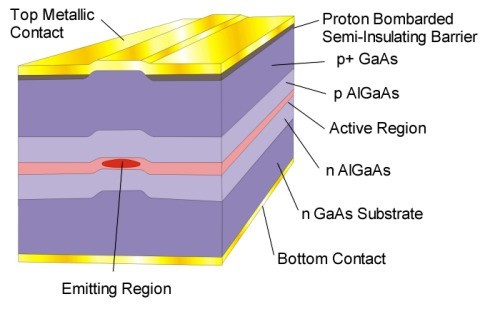

I have a much better image of a nubm substrate stack glowing at threshold and above and you can see the tiny slit at the P/N junction behind the front facet where all the photons exit, it's amazing it can withstand it, however the substrate stack is hygroscopic and coated to protect it, but it is also under a can ( GBall or window ) with an inert backfill ( likely dry nitrogen ) because when they are de-canned then tiny particulate in the air will burn on the facet at the P/N junction over time damaging the protective coating, this will let moisture from the air in and cause fractures greatly reducing the MTTF

This is not my image, these are from endurance lasers, but you can see how tiny the substrate stack is, imagine a small slit center of the front facet, it needs the can and backfill above a couple of watts. Note the part on the left is the anti-static device.