Hey CDBEAM777 how's your build going?

By the way I answered CDBEAM777 thru a pm about the gitd o-rings but just in case someone else will like to know those are 17mm x 1.5mm gitd o-rings. In day light (when not glowing) they look blue. I got them a long time ago, really don't remember where I got them from, I know it was from outside the US.

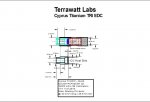

Day job got in the way !!! PLP520 B1 installed in a CU module. I machined a small CU heat sink to contain the module and the driver....a SDX Boost on the back end !!. Very compact and round looking, nice Beam !!!

JR...I decided to use the Europium GITD powder from here....

https://unitednuclear.com/index.php?main_page=index&cPath=28_45

I will mix with some clear epoxy.....and experiment !!

This GITD powder is da Schizz....glows like crazy....the Greens are the best....and the Aqua is a beautiful color !!! The Blue is also a very nice color !!

The Green is the brightest !! ( very, very bright )....the Aqua is very bright....not quite as bright as the Green....and the Blue also glows bright....slightly less than the Green or Aqua !!

This GITD powder is the best I have ever seen !!! We will see how easy it is to mix up...and apply !! The Cyprus EDC has four (4) grooves around the middle...and two (2) grooves on the back. Perhaps I will go with Green/Green/Aqua....and finally Blue !! Dunno !! Perhaps that would look too " Cha-Cha" ?? Dunno ??

Many choices.....The colors do look good side by side !!....Maybe...

Green/Aqua/Blue.....and finally....another Green !! I will apply one (1) ring at a time !!!

Anyway....Pics attached .......and see attached drawing of the machined CU heat sink !! Sorry B-Shot is so lame....My CP camera never get's a good beam shot!!

Will post an update with the rings are filled with the GITD powder/epoxy composite !!

Should be interesting !! Working with goooey epoxy is always such a treat !!!

Anyone have any suggestions on working with this stuff ?? IIRC....1:1 ratio.....and use a 5min clear epoxy !! Like I said....only one (1) ring at a time...then I will let that dry completely !!!....then move on to the next ring !!! I imagine.....I do NOT need to fill the ring completely...only enough to deploy a u channel down in the U shaped ring groove.

:eg::eg:

Now thinking...four (4) centre grooves with Green...Back two (2) grooves...one Aqua and one Blue ??

JR....Thanx for the original inspiration !!!

Thanx fur watch'in !!! ~Beam-out