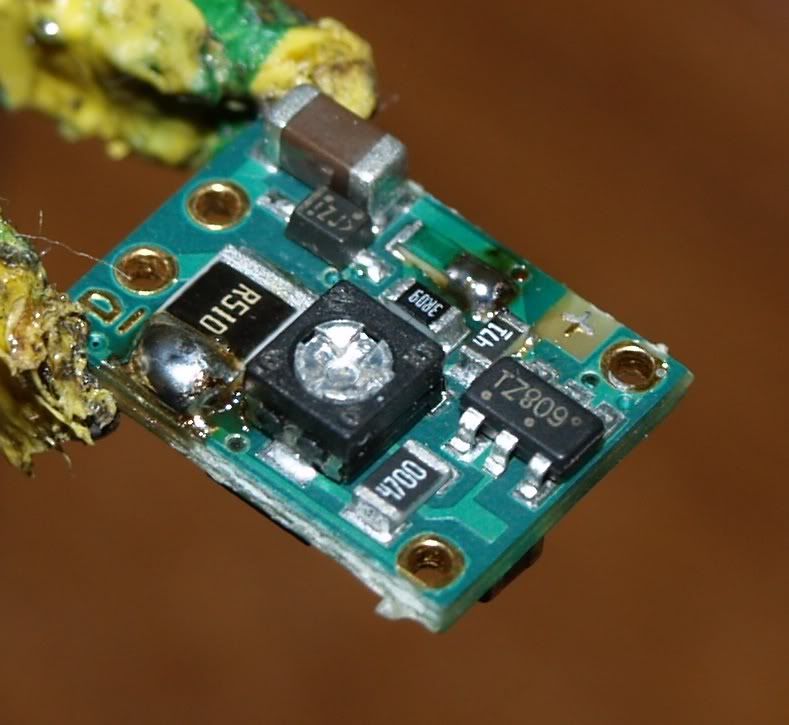

I am working on setting up my microboost driver to drive a 445nm diode close to 1A. I just did the solder bridges the other day and managed to get a little bit more solder than I wanted on one of the bridges. Is this likely going to be a problem? Here is what it looks like:

Boost Driver front by stickyb00t, on Flickr

Notice the big old glob of solder on the lower bridge. Is that going to be okay? It does not appear to be shorting anything else out. Should I attempt to remove some of the solder?

Boost Driver back by stickyb00t, on Flickr

Boost Driver front by stickyb00t, on Flickr

Notice the big old glob of solder on the lower bridge. Is that going to be okay? It does not appear to be shorting anything else out. Should I attempt to remove some of the solder?

Boost Driver back by stickyb00t, on Flickr

Last edited: