Sigurthr

0

- Joined

- Dec 11, 2011

- Messages

- 4,364

- Points

- 83

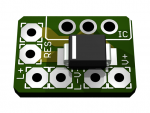

That's excellent news, TJ! Good to see Max is on top of things. A half cyllinder heatsink of the right size could probably solve the problem. I've debated trying to thermal epoxy one on my laser's driver, but I don't have anything that would fit, nor do I have the equipment to make something.

Edit; RHD's got a point. I have no idea about the business model Max has though, it may not be feasible for him to make the drivers or have them specially made. he might be looking for something off the shelf, so to speak.

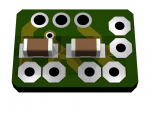

I will say this though.. don't completely cover the driver in epoxy in the future! Mine is literally covered in it, it's like someone took the driver and dipped it in a bucket of epoxy, shook it off, and placed it inside. If I ever want to dissassemble the laser and replace the driver I probably can't without damaging the diode's pins. I know user maintenance and modification is not usually on the scope of the retailer/manufacturer, but I don't see how Lazerer would be able to replace a bad driver this way either... they'd have to replace the entire module just as I would have to. Simply not coating the driver in epoxy would make repairs on returns a lot easier and cost effective, and who knows, it might not overheat so much if air can get to the chips!

Edit; RHD's got a point. I have no idea about the business model Max has though, it may not be feasible for him to make the drivers or have them specially made. he might be looking for something off the shelf, so to speak.

I will say this though.. don't completely cover the driver in epoxy in the future! Mine is literally covered in it, it's like someone took the driver and dipped it in a bucket of epoxy, shook it off, and placed it inside. If I ever want to dissassemble the laser and replace the driver I probably can't without damaging the diode's pins. I know user maintenance and modification is not usually on the scope of the retailer/manufacturer, but I don't see how Lazerer would be able to replace a bad driver this way either... they'd have to replace the entire module just as I would have to. Simply not coating the driver in epoxy would make repairs on returns a lot easier and cost effective, and who knows, it might not overheat so much if air can get to the chips!

Last edited: