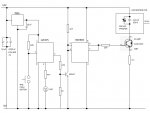

Another small step forward. Making a sturdy Aluminium rail for the Laser assembly and the Optics. I have mounted the Laser Pump Chamber and the Adjustable Mirror Mounts. The alignment of the Rod to Mirrors should be very close. Then the mirrors can be adjusted later using a small pointer. I will start off using 20mm mirrors for the HR and OC. I have a Pyrex 99.7% for the HR mirror with an AR coating for 633-694nm and I will use a 1064nm as the OC. At 694 the 1064 Mirror should have the correct reflection. I can check it with a 650 pointer and see if I get around 30-50% Reflection.

Some pics

Some pics