rhd

0

- Joined

- Dec 7, 2010

- Messages

- 8,469

- Points

- 0

We've got a ton of linear drivers popping up these days, but I think this one is special enough to warrant a thread! Also, I know we see a lot of "vapourware" here, but I have a decent track record of actually bringing these drivers designs out in physical form (even though I don't really have a decent setup for selling any of them at decent prices in volume).

Here's the cool part. As long as it works as expected, I'm going to post the schematic and PCB files for the forum (that seems like the best solution to my inability to practically sell any of my own drivers). Everyone will be free to use the driver as they see fit. I would ask (honour system) that if anyone actually sells the driver (or a close derivative made from the files I post) commercially, that they toss $1 in my direction per driver they sell.

I designed it for the purpose of replacing my Mosquito Red drivers that use the AMC7135, largely because of the incredible difficulty of finding a reasonable North American source for the AMC7135. I was also frustrated with having to deal in 350mA increments, and as small as they are, using four AMC7135 ICs to achieve 1.4A adds some size.

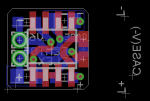

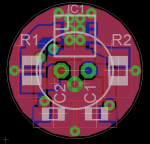

This driver:

- Uses a single STCS1 IC

- Has a total driver dropout of 0.5V

- Measures only... 8mm x 8mm!

That's the neat part! At less than a tenth of a square inch, this guy is 42% smaller than a FlexDrive, and will handle current from 0 to 1500 mA. Specifically speaking, it will be great for two scenarios:

1) Driving Mitsubishi 300 and 500 diodes (at up to 1500mA for the 500s) from 1-cell.

2) Driving BluRay 405nm 12x at up to their absolute max current (600mA) from 2-cells.

More generally, it will work great for almost any Red or BluRay diode. It will also work fine for 445s, but since you're going to be dropping the extra voltage (even though the driver's dropout is low), you'd need to heatsink it. Otherwise, for BluRay or Red, no heatsinking should be required.

Here's the cool part. As long as it works as expected, I'm going to post the schematic and PCB files for the forum (that seems like the best solution to my inability to practically sell any of my own drivers). Everyone will be free to use the driver as they see fit. I would ask (honour system) that if anyone actually sells the driver (or a close derivative made from the files I post) commercially, that they toss $1 in my direction per driver they sell.

I designed it for the purpose of replacing my Mosquito Red drivers that use the AMC7135, largely because of the incredible difficulty of finding a reasonable North American source for the AMC7135. I was also frustrated with having to deal in 350mA increments, and as small as they are, using four AMC7135 ICs to achieve 1.4A adds some size.

This driver:

- Uses a single STCS1 IC

- Has a total driver dropout of 0.5V

- Measures only... 8mm x 8mm!

That's the neat part! At less than a tenth of a square inch, this guy is 42% smaller than a FlexDrive, and will handle current from 0 to 1500 mA. Specifically speaking, it will be great for two scenarios:

1) Driving Mitsubishi 300 and 500 diodes (at up to 1500mA for the 500s) from 1-cell.

2) Driving BluRay 405nm 12x at up to their absolute max current (600mA) from 2-cells.

More generally, it will work great for almost any Red or BluRay diode. It will also work fine for 445s, but since you're going to be dropping the extra voltage (even though the driver's dropout is low), you'd need to heatsink it. Otherwise, for BluRay or Red, no heatsinking should be required.

Attachments

Last edited: