- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

Hello forum!

Here is another nice pyro-tutorial

This time I will explain how to prepare a powerful KP granulated powder.

The same procedure can be applied also to make classical BP powder.

Until the mix is wetted, there is no danger of deflagration, but when the mix is granulated

and well dried it become extremely reactive and dangerous, so do not try to manage

the dried powders at home or inside closed rooms!

Please avoid synthetic clothes or other yarns that can spark, always use brass or lead medias, silicon spoons,

wear gloves and filtering masks.

If possible maintain the naked feet on the floor or use a antistatic bracelet connected to the ground.

Some big moistened rags near the working area are suggested to limit damages or injiuries in the worst scenario.

KP powder is similar to the BP powder but much more reactive because the Potassium Nitrate is replaced

with Potassium Perchlorate.

The percentage of each chem is slightly different form the BP formula.

You need Potassium Perchlorate (KCLO4), Sulfur, fast Charcoal and Dextrin:

Placing 100x1cm diameter brass balls in the bottom of a rock thumbler cylinder:

Filling the barrell with 70% KCLO4, 18% Charcoal, 12% Sulfur.

Add 2 grams of dextrin every 100 parts of the mix: this allow to create solid grains when they are dried,

otherwise the grains will be weak and friable.

The amount of the total weight powders involved is proportionally to the barrell size.

Usually the best choice is to fill the media with powders just a little bit over them:

Adding enough denatured alcohol to create a slurry mix. The mix must be quite liquid.

If You do not hear the medias hit one against another during the mill process, the mix is too dense and You need to add more alcohol:

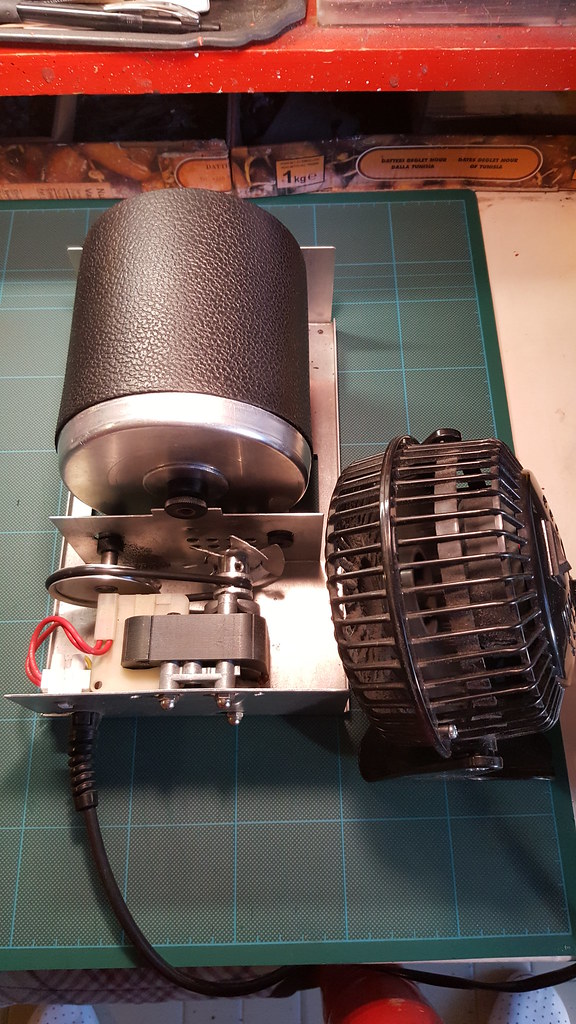

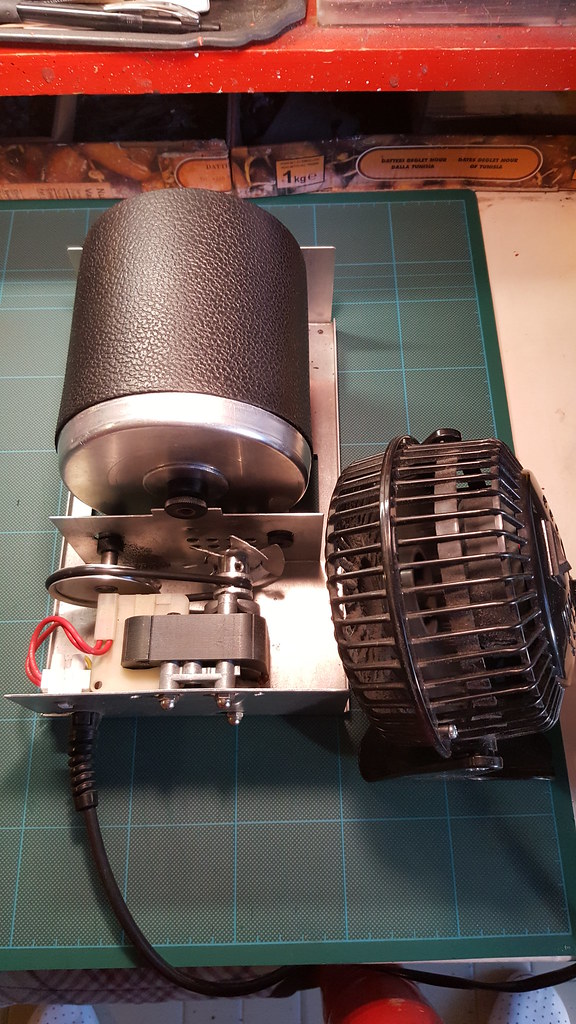

Starting to mill the slurry mix. I had to open the device box and put a fan to cool the motor because the brass balls

are heavy and the motor will be stressed out.

Usually with 100 brass balls, the barrell correctly filled and the right rotation speed, 1-2 hours is the right choice:

After the milling, stop the device, extract the barrell, put it in vertical position, and wait at least 1 hour to allow the decantation of the mix

on the bottom. In that way You can save some alcohol useful for another milling process:

If You want You can tilt the barrell to facilitate the alcohol recovery:

Now separing the slurry mix from the media balls with the aid of a kitchen strainer and spreading it over a waxed paper:

After some hours most of the alcohol is evaporated and the mix tends to break:

Breaking all the plaques with hands to create a raw mix:

Wet the powder with enough demineralized water:

Make solid balls pressing the wetted mix with the hands.

If You are unable to make compact rounded balls because the mix is friable You need to add other demineralized water.

If the balls are too wetted they will not hold their form and sit down like a molten blob, so You need to add some dry mix.

This is a foolproof try-and-error method:

Break the balls in two parts like an apple, then press and crawl at the same time one half by time with the hands along a 8 mesh woven wire

If You make correctly this passage, You will obtain much 8 mesh grains and very few 20+ mesh powder (also called meal).

Under the 8 mesh woven wire there will be a 20 mesh one. The 8 mesh grains will be captured and will rests over the surface, while the 20+ mesh grains will cross the 20 mesh voven wire and will be caught in the drawer at the lowest point of the device:

And finally the dried powders:

It is very important to make perfectly dried powders to obtain a maximum burst performance.

Usually, after the first passage with my drying device (only suction fans, no heat), I use a semi-professional

dehydratator at 122 °F for one hour to be sure that no water or alcohol is trapped inside the grains.

After cooling the powders it is a good idea to place them inside hermetic boxes with some drying bags.

That's all!

Richard.

Here is another nice pyro-tutorial

This time I will explain how to prepare a powerful KP granulated powder.

The same procedure can be applied also to make classical BP powder.

Until the mix is wetted, there is no danger of deflagration, but when the mix is granulated

and well dried it become extremely reactive and dangerous, so do not try to manage

the dried powders at home or inside closed rooms!

Please avoid synthetic clothes or other yarns that can spark, always use brass or lead medias, silicon spoons,

wear gloves and filtering masks.

If possible maintain the naked feet on the floor or use a antistatic bracelet connected to the ground.

Some big moistened rags near the working area are suggested to limit damages or injiuries in the worst scenario.

KP powder is similar to the BP powder but much more reactive because the Potassium Nitrate is replaced

with Potassium Perchlorate.

The percentage of each chem is slightly different form the BP formula.

You need Potassium Perchlorate (KCLO4), Sulfur, fast Charcoal and Dextrin:

Placing 100x1cm diameter brass balls in the bottom of a rock thumbler cylinder:

Filling the barrell with 70% KCLO4, 18% Charcoal, 12% Sulfur.

Add 2 grams of dextrin every 100 parts of the mix: this allow to create solid grains when they are dried,

otherwise the grains will be weak and friable.

The amount of the total weight powders involved is proportionally to the barrell size.

Usually the best choice is to fill the media with powders just a little bit over them:

Adding enough denatured alcohol to create a slurry mix. The mix must be quite liquid.

If You do not hear the medias hit one against another during the mill process, the mix is too dense and You need to add more alcohol:

Starting to mill the slurry mix. I had to open the device box and put a fan to cool the motor because the brass balls

are heavy and the motor will be stressed out.

Usually with 100 brass balls, the barrell correctly filled and the right rotation speed, 1-2 hours is the right choice:

After the milling, stop the device, extract the barrell, put it in vertical position, and wait at least 1 hour to allow the decantation of the mix

on the bottom. In that way You can save some alcohol useful for another milling process:

If You want You can tilt the barrell to facilitate the alcohol recovery:

Now separing the slurry mix from the media balls with the aid of a kitchen strainer and spreading it over a waxed paper:

After some hours most of the alcohol is evaporated and the mix tends to break:

Breaking all the plaques with hands to create a raw mix:

Wet the powder with enough demineralized water:

Make solid balls pressing the wetted mix with the hands.

If You are unable to make compact rounded balls because the mix is friable You need to add other demineralized water.

If the balls are too wetted they will not hold their form and sit down like a molten blob, so You need to add some dry mix.

This is a foolproof try-and-error method:

Break the balls in two parts like an apple, then press and crawl at the same time one half by time with the hands along a 8 mesh woven wire

If You make correctly this passage, You will obtain much 8 mesh grains and very few 20+ mesh powder (also called meal).

Under the 8 mesh woven wire there will be a 20 mesh one. The 8 mesh grains will be captured and will rests over the surface, while the 20+ mesh grains will cross the 20 mesh voven wire and will be caught in the drawer at the lowest point of the device:

And finally the dried powders:

It is very important to make perfectly dried powders to obtain a maximum burst performance.

Usually, after the first passage with my drying device (only suction fans, no heat), I use a semi-professional

dehydratator at 122 °F for one hour to be sure that no water or alcohol is trapped inside the grains.

After cooling the powders it is a good idea to place them inside hermetic boxes with some drying bags.

That's all!

Richard.

Last edited: