LyncHung

0

- Joined

- Jan 23, 2010

- Messages

- 29

- Points

- 0

So I got a 5mW green laser from DealExtreme (http://www.dealextreme.com/details.dx/sku.91). After a few days it stopped working, after looking closely, the wire that attached to the frame had become disconnected. After barely touching it the wire fell out, broke off from the solder point.

So i FINALLY got the laser apart (pain in @$$). I really wish i had a good camera to take pics, but all i got is others pics, so please bear with me.

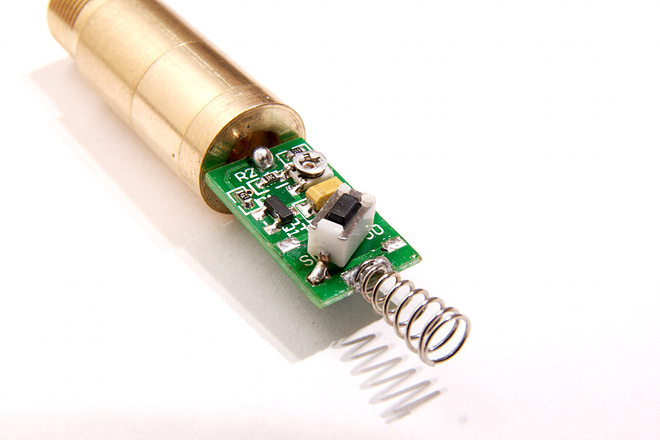

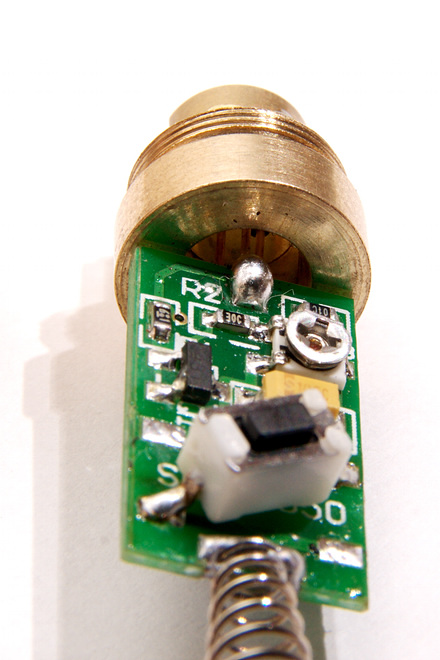

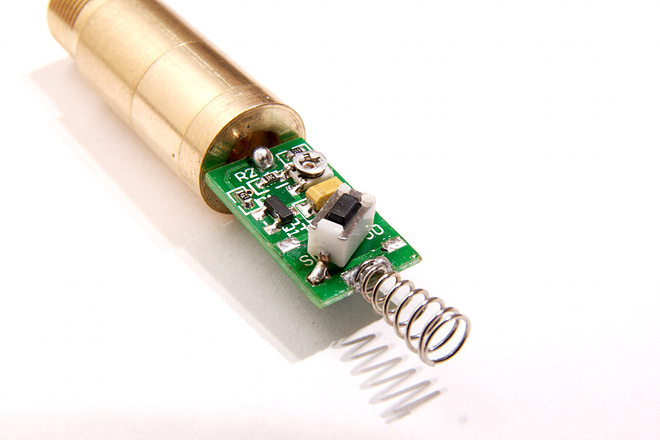

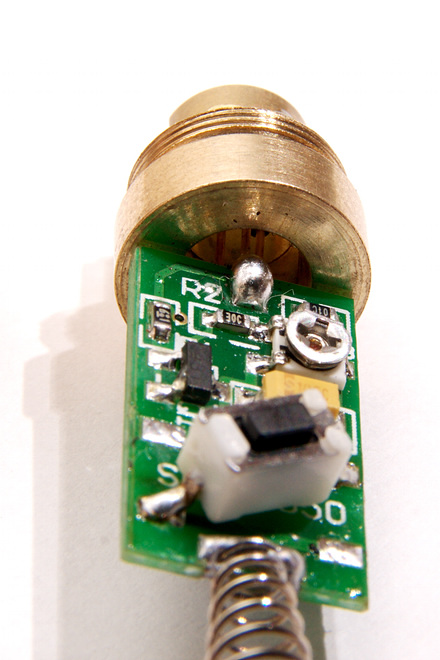

Here's what i got now, EXCEPT for the switch, this is a replacement switch someone installed, other than that it is exactly the same as i got now:

The button on there now has 4 leads on it and i can't tell which one the power wire broke off of. What i would really like to do is just bypass the button switch, and just run the laser off of a little DC converter (like an old cell phone charger).

Now i got a little electronics experience, but i suck at soldering, don't even have a soldering iron.

So should i follow the switch from the pictures and just place a wire over those pins or could mine be different wiring? everything else looks the same.

Sorry i don't got pics of mine. I'm just a noob with lasers but I'm loving them.

So i FINALLY got the laser apart (pain in @$$). I really wish i had a good camera to take pics, but all i got is others pics, so please bear with me.

Here's what i got now, EXCEPT for the switch, this is a replacement switch someone installed, other than that it is exactly the same as i got now:

The button on there now has 4 leads on it and i can't tell which one the power wire broke off of. What i would really like to do is just bypass the button switch, and just run the laser off of a little DC converter (like an old cell phone charger).

Now i got a little electronics experience, but i suck at soldering, don't even have a soldering iron.

So should i follow the switch from the pictures and just place a wire over those pins or could mine be different wiring? everything else looks the same.

Sorry i don't got pics of mine. I'm just a noob with lasers but I'm loving them.