Turned up some heatsinks for "pen" lasers, will test it a bit later on to see what sort of Duty cycle I can achieve, I am hoping for 100%.

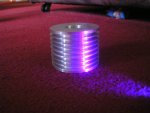

Picture shows my wicked 35mw Advanced with Heatsink fitted, also shown are a sample for Timelord's Viper and Senkat's 100mw red module. As they have power meters they will be able to accurately determine the duty cycle these things can extend to pen type lasers.

For those Interested, they are a simple push fit over the barrel and are turned from aerospace grade Ally bar that can be polished to a mirror finish.

Jase

Picture shows my wicked 35mw Advanced with Heatsink fitted, also shown are a sample for Timelord's Viper and Senkat's 100mw red module. As they have power meters they will be able to accurately determine the duty cycle these things can extend to pen type lasers.

For those Interested, they are a simple push fit over the barrel and are turned from aerospace grade Ally bar that can be polished to a mirror finish.

Jase