kmm5117

0

- Joined

- Mar 25, 2013

- Messages

- 88

- Points

- 0

So I have a question,

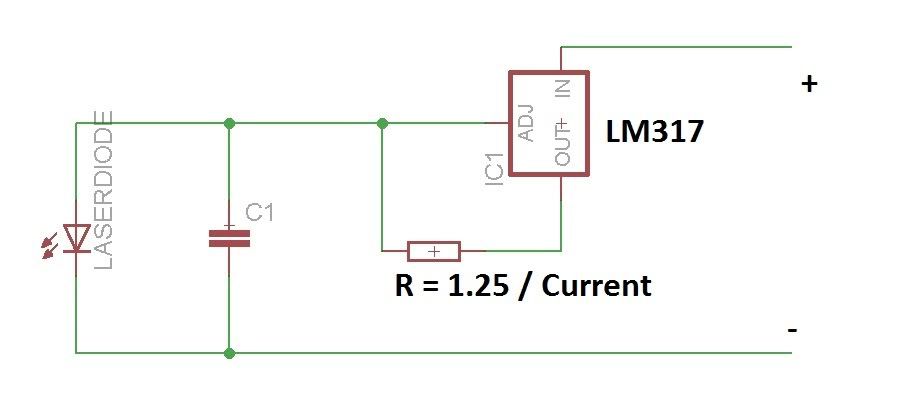

I was working on a simple build using a 300mW red diode and a driver with current set at 400mA. Before i put the laser together and soldered my final connections, I tested the setup and the diode worked fine. So I unhooked what I needed to, and then soldered my final connections and assembled the laser. After everything was completed I powered the laser on and dot a bright beam for a split second and the diode died (LED'd the diode). My question is how did I fry this diode, and how can i prevent it in the future. Is it from not properly discharging the capacitor before connection ? I thought I did, but if that is the case can someone give me a quick run-down on how to properly discharge it?

Thanks

I was working on a simple build using a 300mW red diode and a driver with current set at 400mA. Before i put the laser together and soldered my final connections, I tested the setup and the diode worked fine. So I unhooked what I needed to, and then soldered my final connections and assembled the laser. After everything was completed I powered the laser on and dot a bright beam for a split second and the diode died (LED'd the diode). My question is how did I fry this diode, and how can i prevent it in the future. Is it from not properly discharging the capacitor before connection ? I thought I did, but if that is the case can someone give me a quick run-down on how to properly discharge it?

Thanks