knimrod

0

- Joined

- Nov 4, 2007

- Messages

- 385

- Points

- 0

As promised, here is the DIY Thermal Energy Meter build thread.

This is no way intended to be the end-all and be-all of laser power meters. It's a simplified design intended for the amateur hobbyist. It can be expanded upon but as presented here, it is intended to be an interface between a common multimeter or panel meter, and a currently available, surplus thermopile sensor head intended for some unknown OEM application.

This is a true thermal energy meter and measures laser power accurately over a broad range of wavelengths without recalibration. It is very sensitive (sensitive enough to measure the radiated heat from your body if in front of the sensor!) and has a huge dynamic range. My testing has determined that the sensor head is calibrated to output 1mV per Watt (1uV per mW) of measured thermal energy. In order for the amplifier to output a calibrated 1mV per 1mW of measured power, it needs to multiply its input voltage by 1000. Because it is so sensitive, it is subject to small errors from incident heat radiators and air currents. A shroud around the sensor absorber would probably help reduce these errors. Other, more persistent errors can be nulled out with the optional zero offset feature. The zero offset adjustment can be made with an internal trimmer potentiometer but an externally adjustable potentiometer would be more convenient. While shown as optional, I recommend building the offset circuit into your unit. Otherwise you'll have to manually subtract the zero offset from your measurements

The thermal head assembly is available in an Ebay store for $34.95 shipped. The thermal sensor head can be removed from the PCB fairly easily and there is a 1/4"-20 tapped hole already in its underside for easy mounting to a portable camera tripod or stand. There is also a heater control PCB on the back of the sensor head that can be left in place or removed as it's not used in this design. I believe the heater control was originally intended to keep the sensor head at a controlled temperature because the original application had the sensor head in an enclosed and confined area where the sensor could not give up its accumulated heat very well and thus preventing drift.

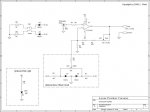

The amplifier consists of a single op-amp stage. The LTC1050 is a zero-drift, chopper stabilized op-amp ideal for our purpose. It's configured for an adjustable gain of ~941 to ~1041. Since we are looking for a gain of ~1000, the gain potentiometer (VR1) should be preset to ~5.9K. This setting should get pretty close to a usable calibration. There may be some component tolerance issues necessitating a more complete calibration if a higher degree of precision is needed. The useful overall range of this amplifier circuit should be 0mW to over 4000mW. The LTC1050 op-amp is not a part available from Radio Shack but can be purchased from Digi-Key. However, the PCB that comes with the sensor head uses this op-amp. It's in location U4 and can be carefully unsoldered and re-used.

I'll leave it up to the individual builder to decide on what's best for a display. My original prototype employs a digital panel meter but DPMs are expensive and varied. A standard multimeter displaying voltage will suffice nicely and the odds are if you are building this, you already have one. I would recommend not limiting yourself too much by the size of the proto-board you use, there may be some additional circuitry you may want to add for future features. A DPM for instance, may require a few extra components for scaling the output or reducing the power supply voltages.

I realize that this design leaves a lot to be desired but I did take great pains to keep it as simple as possible to build with readily available parts. I also realize that it's somewhat inconvenient to use two 9 volt batteries but the easiest way to design this with simplicity in mind was to do it this way. The batteries should last quite a while.

I will be building another amplifier as I envision you will do. I will try to document my progress with comments and pictures as I go. I hope you all will treat this as an "open" group project and comment on your own progress and ideas to make this easier, simpler, and better.

Disclaimer:

I take no responsibility for the accuracy or completeness of the information presented here. I make no warranty either expressed or implied, of the fitness of this information for any purpose. Use this information at your own risk.

First steps:

Order the sensor head assembly (http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=180205936518) and gather up the rest of the parts.

Initial thoughts:

To keep things simple, the cable that connects the sensor head to the original PCB can be re-used. You can chop off the small connector and solder the wires directly to the amplifier PCB. This will eliminate the BNC input jack on the amp and the need to buy or make a BNC cable.

The input of the amplifier is very sensitive. Some care should be exercised when placing components and wires.

A printed circuit board is available in limited quantities.

At some point, I may design a microcontroller addition to read the voltage and send it out over a serial or USB interface.

My original meter employs a DPM. The amplifier in this one is messy as I made many running changes to get it to a point I was happy with it.

My original meter employs a DPM. The amplifier in this one is messy as I made many running changes to get it to a point I was happy with it.

The schematic is attached to this post. I'll attach the parts list to the next post.

(edited 1/12/08 to reflect price increase and change in link for the thermal sensor)

(edited 1/23/08 to upload the revision C schematic)

This is no way intended to be the end-all and be-all of laser power meters. It's a simplified design intended for the amateur hobbyist. It can be expanded upon but as presented here, it is intended to be an interface between a common multimeter or panel meter, and a currently available, surplus thermopile sensor head intended for some unknown OEM application.

This is a true thermal energy meter and measures laser power accurately over a broad range of wavelengths without recalibration. It is very sensitive (sensitive enough to measure the radiated heat from your body if in front of the sensor!) and has a huge dynamic range. My testing has determined that the sensor head is calibrated to output 1mV per Watt (1uV per mW) of measured thermal energy. In order for the amplifier to output a calibrated 1mV per 1mW of measured power, it needs to multiply its input voltage by 1000. Because it is so sensitive, it is subject to small errors from incident heat radiators and air currents. A shroud around the sensor absorber would probably help reduce these errors. Other, more persistent errors can be nulled out with the optional zero offset feature. The zero offset adjustment can be made with an internal trimmer potentiometer but an externally adjustable potentiometer would be more convenient. While shown as optional, I recommend building the offset circuit into your unit. Otherwise you'll have to manually subtract the zero offset from your measurements

The thermal head assembly is available in an Ebay store for $34.95 shipped. The thermal sensor head can be removed from the PCB fairly easily and there is a 1/4"-20 tapped hole already in its underside for easy mounting to a portable camera tripod or stand. There is also a heater control PCB on the back of the sensor head that can be left in place or removed as it's not used in this design. I believe the heater control was originally intended to keep the sensor head at a controlled temperature because the original application had the sensor head in an enclosed and confined area where the sensor could not give up its accumulated heat very well and thus preventing drift.

The amplifier consists of a single op-amp stage. The LTC1050 is a zero-drift, chopper stabilized op-amp ideal for our purpose. It's configured for an adjustable gain of ~941 to ~1041. Since we are looking for a gain of ~1000, the gain potentiometer (VR1) should be preset to ~5.9K. This setting should get pretty close to a usable calibration. There may be some component tolerance issues necessitating a more complete calibration if a higher degree of precision is needed. The useful overall range of this amplifier circuit should be 0mW to over 4000mW. The LTC1050 op-amp is not a part available from Radio Shack but can be purchased from Digi-Key. However, the PCB that comes with the sensor head uses this op-amp. It's in location U4 and can be carefully unsoldered and re-used.

I'll leave it up to the individual builder to decide on what's best for a display. My original prototype employs a digital panel meter but DPMs are expensive and varied. A standard multimeter displaying voltage will suffice nicely and the odds are if you are building this, you already have one. I would recommend not limiting yourself too much by the size of the proto-board you use, there may be some additional circuitry you may want to add for future features. A DPM for instance, may require a few extra components for scaling the output or reducing the power supply voltages.

I realize that this design leaves a lot to be desired but I did take great pains to keep it as simple as possible to build with readily available parts. I also realize that it's somewhat inconvenient to use two 9 volt batteries but the easiest way to design this with simplicity in mind was to do it this way. The batteries should last quite a while.

I will be building another amplifier as I envision you will do. I will try to document my progress with comments and pictures as I go. I hope you all will treat this as an "open" group project and comment on your own progress and ideas to make this easier, simpler, and better.

Disclaimer:

I take no responsibility for the accuracy or completeness of the information presented here. I make no warranty either expressed or implied, of the fitness of this information for any purpose. Use this information at your own risk.

First steps:

Order the sensor head assembly (http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=180205936518) and gather up the rest of the parts.

Initial thoughts:

To keep things simple, the cable that connects the sensor head to the original PCB can be re-used. You can chop off the small connector and solder the wires directly to the amplifier PCB. This will eliminate the BNC input jack on the amp and the need to buy or make a BNC cable.

The input of the amplifier is very sensitive. Some care should be exercised when placing components and wires.

A printed circuit board is available in limited quantities.

At some point, I may design a microcontroller addition to read the voltage and send it out over a serial or USB interface.

The schematic is attached to this post. I'll attach the parts list to the next post.

(edited 1/12/08 to reflect price increase and change in link for the thermal sensor)

(edited 1/23/08 to upload the revision C schematic)