- Joined

- May 4, 2009

- Messages

- 5,426

- Points

- 113

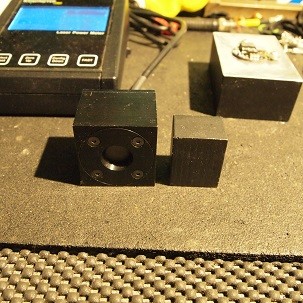

Bricks are fine but a little big, I have a simple cube of aluminum painted black

with plain old flat black spray paint and it works just fine for me, I keep it next

to the OPHIR head of my LPM and when I'm getting ready to measure a laser

diode with a lens in front of it I always point the laser at the block first to be

sure it is not set to a pin point and if it is I un-focus it or spread the beam

out to at least 1/4" wide before pointing it at the OPHIR sensor.

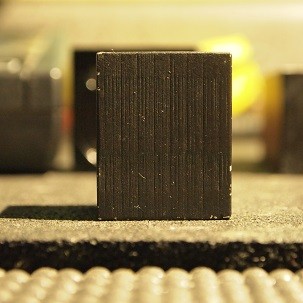

Just a simple cube of Al painted black

Ready to meter a laser

with plain old flat black spray paint and it works just fine for me, I keep it next

to the OPHIR head of my LPM and when I'm getting ready to measure a laser

diode with a lens in front of it I always point the laser at the block first to be

sure it is not set to a pin point and if it is I un-focus it or spread the beam

out to at least 1/4" wide before pointing it at the OPHIR sensor.

Just a simple cube of Al painted black

Ready to meter a laser