Pixeljoch

New member

- Joined

- Dec 10, 2020

- Messages

- 4

- Points

- 3

Hey there! So this thread is basically a way for me to document my progress on my boost driver and to share what I currently have, discussions, you know the deal.

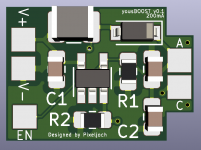

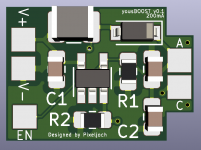

So to get started. The goal is to eventually get a high efficiency 1A boost driver in the smallest possible formfactor I can manage. Current dimensions are 11x16mm, which is not bad, but I've definitely seen smaller. I finally got a working prototype and I tested it on a few different diodes, each with a different operating voltage, all on 200mA. Vin is set on 3.7V, to mimic a Li-Ion battery. On a PL450B, it steps up the voltage to 5.2V, and it draws about 490mA. The efficiency is about 57%, which sucks honestly.

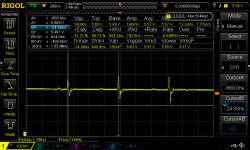

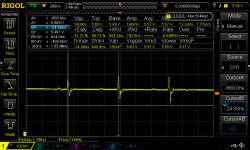

The ripple isn't any better. When settled its about 160mV p-p while I aimed for 50mV p-p. From what I understand currently is that the caps I used apparently decrease in capacity the higher the frequency gets. When it reaches 1.6MHz, the capacity will have dropped more than half. So replacing them with some caps that are meant for switch-mode power supplies, will hopefully solve the problem. I also tested the driver on a 488nm laser diode, which is known to have a very high operating voltage. The driver easily sucks 900mA to boost it to 6.7V at 200mA and the efficiency drops to an appalling 40%. Ripple is practically the same as the PL450B. I did decide to put this diode into a small keychain laser and it worked surprisingly well.

When it comes to heat, when supplying the PL450B, the driver stayed relatively cool when running for a small while. On the 488nm though, it gets pretty warm after about 30 seconds of continues firing. I'll have to redo the layout and pick the components more carefully next time in order to get the efficiency up and so I don't produce as much waste heat.

That's all for today! So there's definitely still a lot I can improve upon! Exams are coming up though, so I'll have to focus on that for a bit, but I'll still update this thread regularly when developments are made.

So to get started. The goal is to eventually get a high efficiency 1A boost driver in the smallest possible formfactor I can manage. Current dimensions are 11x16mm, which is not bad, but I've definitely seen smaller. I finally got a working prototype and I tested it on a few different diodes, each with a different operating voltage, all on 200mA. Vin is set on 3.7V, to mimic a Li-Ion battery. On a PL450B, it steps up the voltage to 5.2V, and it draws about 490mA. The efficiency is about 57%, which sucks honestly.

The ripple isn't any better. When settled its about 160mV p-p while I aimed for 50mV p-p. From what I understand currently is that the caps I used apparently decrease in capacity the higher the frequency gets. When it reaches 1.6MHz, the capacity will have dropped more than half. So replacing them with some caps that are meant for switch-mode power supplies, will hopefully solve the problem. I also tested the driver on a 488nm laser diode, which is known to have a very high operating voltage. The driver easily sucks 900mA to boost it to 6.7V at 200mA and the efficiency drops to an appalling 40%. Ripple is practically the same as the PL450B. I did decide to put this diode into a small keychain laser and it worked surprisingly well.

When it comes to heat, when supplying the PL450B, the driver stayed relatively cool when running for a small while. On the 488nm though, it gets pretty warm after about 30 seconds of continues firing. I'll have to redo the layout and pick the components more carefully next time in order to get the efficiency up and so I don't produce as much waste heat.

That's all for today! So there's definitely still a lot I can improve upon! Exams are coming up though, so I'll have to focus on that for a bit, but I'll still update this thread regularly when developments are made.