Hey guys,

I did another run and got an output between the high 2500mW to the low 2600mW so about 100mW's above spec. Do you think the previous owner simply had peaks when he recorded 2.8 & 2.7W's? So what it averages on output is what im getting?

-Alex

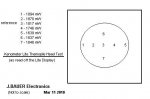

You might want to consider purchasing a fresh/new sensor form Laserbee if you caused smoke to come out of yours and consider testing a more rational way as Seoul_laseers suggests "The laser output should more or less cover the sensors surface (50-90%). (defocused) and centred."

Is hard to figure what you are trying to determine and why.

Questions about the seller that nobody can answer --If you want to know why your LPM reading and the sellers readings are different you can guess. Different time different place different conditions , different LPM and so on. Why don't you just email him and ask + see if he has the original test data and spec details that came with your MGL-F-532 2.5W--if not email CNI and see if they can email you a copy of the test data/spec for that particular serial number--then you would actually know what you have or at least how it started out in life.

Last edited: