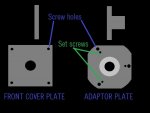

Yes I have owned the JL 10X before but I center my module so I wont have any positional run out, the only possibility would be angular run out if the diode is not pressed perpendicular but the JL won't adjust for angle, just position and that wont be a factor....actually I would like to use this BE with a c-lens pair corrected 44 so I would use an adaptor that I can remove rather than milling the endplate in to a round bar, this way I can make sure the angle will be correct as I will set my laser 1st and center it for height and angle then attach the endplate and make sure it's centered, then remove the endplate and set my 6X pair along the straight and level beam path, then attach the endplate adaptor and make sure it's correct before curing my UV glue, simply oversizing the 4 corner adaptor plate screw holes by a drill size or two would let me cheat if it was not aligned but I will make sure it is to start and throughout the process, also I build my boxes from 1/4 inch plate/bar so there's plenty of overlap to seal the box if I did have to cheat a little but I don't plan to do that.

I had started out doing round/cylinder head builds with the 12mm copper module set in the heat sink center hole like in the 2nd pic, but I want to do more square head builds with the linear motion rail mounts like in the top pic, I like them better for several reasons, aesthetics are my least concern........well not my top concern for certain as these builds are for me.

View attachment 62502

View attachment 62503