Fiddy

0

- Joined

- May 22, 2011

- Messages

- 2,726

- Points

- 63

G'day,

So lately Ive been wavelength hunting, and when i stumbled upon a Class 4 670-690 diode i got excited.

Its a 500mW 670-690nm T0-3 diode on eBay, i plan to put it into a host, a fairly large one.

Spec sheet: COHERENT S-67-500C-100-Q

The unit has a TEC and thermistor but i dont intend on running them at this stage.

The diode is also case positive, so ive done some testing with drivers and i can use a 16 mode AMC-7135 boards i love, ill use 3x AMC chips to regulate 1050mA which is what the spec sheet says it can handle.

Im going to run the battery case positive, but a problem arises there, the AMC-7135 driver contact patch is a Positive patch, to get around this, im going to have a blank contact board, with a black wire coming off the the center positive contact patch, going to the negative on the AMC driver! Doesn't make sense? here's a diagram of what i intend.

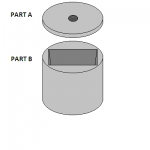

Now for the mounting of the diode, i plan to make my own mount out of aluminum based on the dimensions on the spec sheet, Now my paint drawings art great but here's a diagram of what i plan on:

Does that seem like a good way to mount this? do you have a better idea that i can make? im open to suggestions.

Also could you recommend a decent host that fits the following criteria:

Any help,tips would be appreciated!

Cheers!

Fidz.

So lately Ive been wavelength hunting, and when i stumbled upon a Class 4 670-690 diode i got excited.

Its a 500mW 670-690nm T0-3 diode on eBay, i plan to put it into a host, a fairly large one.

Spec sheet: COHERENT S-67-500C-100-Q

The unit has a TEC and thermistor but i dont intend on running them at this stage.

The diode is also case positive, so ive done some testing with drivers and i can use a 16 mode AMC-7135 boards i love, ill use 3x AMC chips to regulate 1050mA which is what the spec sheet says it can handle.

Im going to run the battery case positive, but a problem arises there, the AMC-7135 driver contact patch is a Positive patch, to get around this, im going to have a blank contact board, with a black wire coming off the the center positive contact patch, going to the negative on the AMC driver! Doesn't make sense? here's a diagram of what i intend.

Now for the mounting of the diode, i plan to make my own mount out of aluminum based on the dimensions on the spec sheet, Now my paint drawings art great but here's a diagram of what i plan on:

Does that seem like a good way to mount this? do you have a better idea that i can make? im open to suggestions.

Also could you recommend a decent host that fits the following criteria:

- voltage must be 4.2V max in, so single cell or multli parallel batteries.

- At least 50mm in head diameter, at least 40-45mm reflector size (diode is 39mm wide).

- Cant be a saik, TK-35 or a RL-2088 as i have one of them already

Any help,tips would be appreciated!

Cheers!

Fidz.

Last edited: