Hello folks.

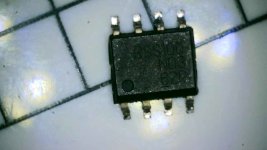

I accidently damaged a nice laser driver. Instead of a diode i hooked a small 5V electromotor on it, i wanted to see if it makes a good testload. View seconds later theres was a little smoke and the black part with the 8 pins came off, obviously its soldering points got too hot and that little part was like "F... that im leaving".

Now this part isnt particularly expensive, but i think it might be a good practice to solder such delicate and small things. Im not even sure if it is salvageable. I tried following so far:

i set the part exactly in the position it was and then tried to heat the board up from the backside, hoping the heat gets through and melts this soldering points again. Now that didnt work, board is thicker as you might think and i only have this 30w crappy soldering iron. I do have a heatgun that goes to 600 C, problem even on lowest air volume setting it puts out a lot of air. Also it has huge diameter at the air outtake, more than an inch.

Plus i dropped that thing and now i dont know which way that thing(i think a transistor)was soldered to the board.

Can anyone maybe give advice how to proceed or guess if it is still working?

thank you.(edit yeah i should admit im a soldering noob. I managed to desolder a few caps and coils from an old mainboard and PSU over the last weeks, but thats it)

I accidently damaged a nice laser driver. Instead of a diode i hooked a small 5V electromotor on it, i wanted to see if it makes a good testload. View seconds later theres was a little smoke and the black part with the 8 pins came off, obviously its soldering points got too hot and that little part was like "F... that im leaving".

Now this part isnt particularly expensive, but i think it might be a good practice to solder such delicate and small things. Im not even sure if it is salvageable. I tried following so far:

i set the part exactly in the position it was and then tried to heat the board up from the backside, hoping the heat gets through and melts this soldering points again. Now that didnt work, board is thicker as you might think and i only have this 30w crappy soldering iron. I do have a heatgun that goes to 600 C, problem even on lowest air volume setting it puts out a lot of air. Also it has huge diameter at the air outtake, more than an inch.

Plus i dropped that thing and now i dont know which way that thing(i think a transistor)was soldered to the board.

Can anyone maybe give advice how to proceed or guess if it is still working?

thank you.(edit yeah i should admit im a soldering noob. I managed to desolder a few caps and coils from an old mainboard and PSU over the last weeks, but thats it)

Attachments

Last edited: