Alright I'm designing a laser scanning device that uses a polygon mirror motor found in laser printers.

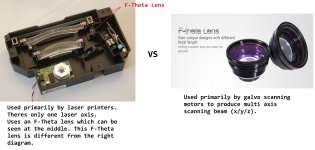

The laser beam must always be in focus to get the highest resolution scans, therefore all laser printers uses a "F-Theta" lens so that the laser beam

focal point will always be in focus for the entire scanning surface. F-Theta lens used in laser printers are specifically designed for 1 axis laser scans only.

Heres the problem, the F-Theta lens found in laser printers are not designed for the UV wavelength lasers such as 405nm. They originally use a different wavelength most likely infrared.

I spent days searching on the internet to find a company/manufacturer that sells these 1 axis F-Theta lens and couldn't find any.

Anyone here knows a company or maybe probably can tell me how I can make my own F-Theta lens used specifically for 405nm lasers?

(Yes, I know many factors must be know such as the polygon mirror size and scanning distance etc... etc)

I do not want to use the multi axis f-theta lens used with galvo scanning motors. I would like to use f-theta lens specifically for 1 axis scans.

Have any other ideas how I can get the focal point always in focus throughout the entire 1 axis?

Please view the attached picture so that you can get an idea what I am talking about.

Also please do not mention about other people's project which is irrelevant to mine, I do not want to use a transparent prism.

Thanks.

The laser beam must always be in focus to get the highest resolution scans, therefore all laser printers uses a "F-Theta" lens so that the laser beam

focal point will always be in focus for the entire scanning surface. F-Theta lens used in laser printers are specifically designed for 1 axis laser scans only.

Heres the problem, the F-Theta lens found in laser printers are not designed for the UV wavelength lasers such as 405nm. They originally use a different wavelength most likely infrared.

I spent days searching on the internet to find a company/manufacturer that sells these 1 axis F-Theta lens and couldn't find any.

Anyone here knows a company or maybe probably can tell me how I can make my own F-Theta lens used specifically for 405nm lasers?

(Yes, I know many factors must be know such as the polygon mirror size and scanning distance etc... etc)

I do not want to use the multi axis f-theta lens used with galvo scanning motors. I would like to use f-theta lens specifically for 1 axis scans.

Have any other ideas how I can get the focal point always in focus throughout the entire 1 axis?

Please view the attached picture so that you can get an idea what I am talking about.

Also please do not mention about other people's project which is irrelevant to mine, I do not want to use a transparent prism.

Thanks.