- Joined

- Aug 31, 2016

- Messages

- 963

- Points

- 93

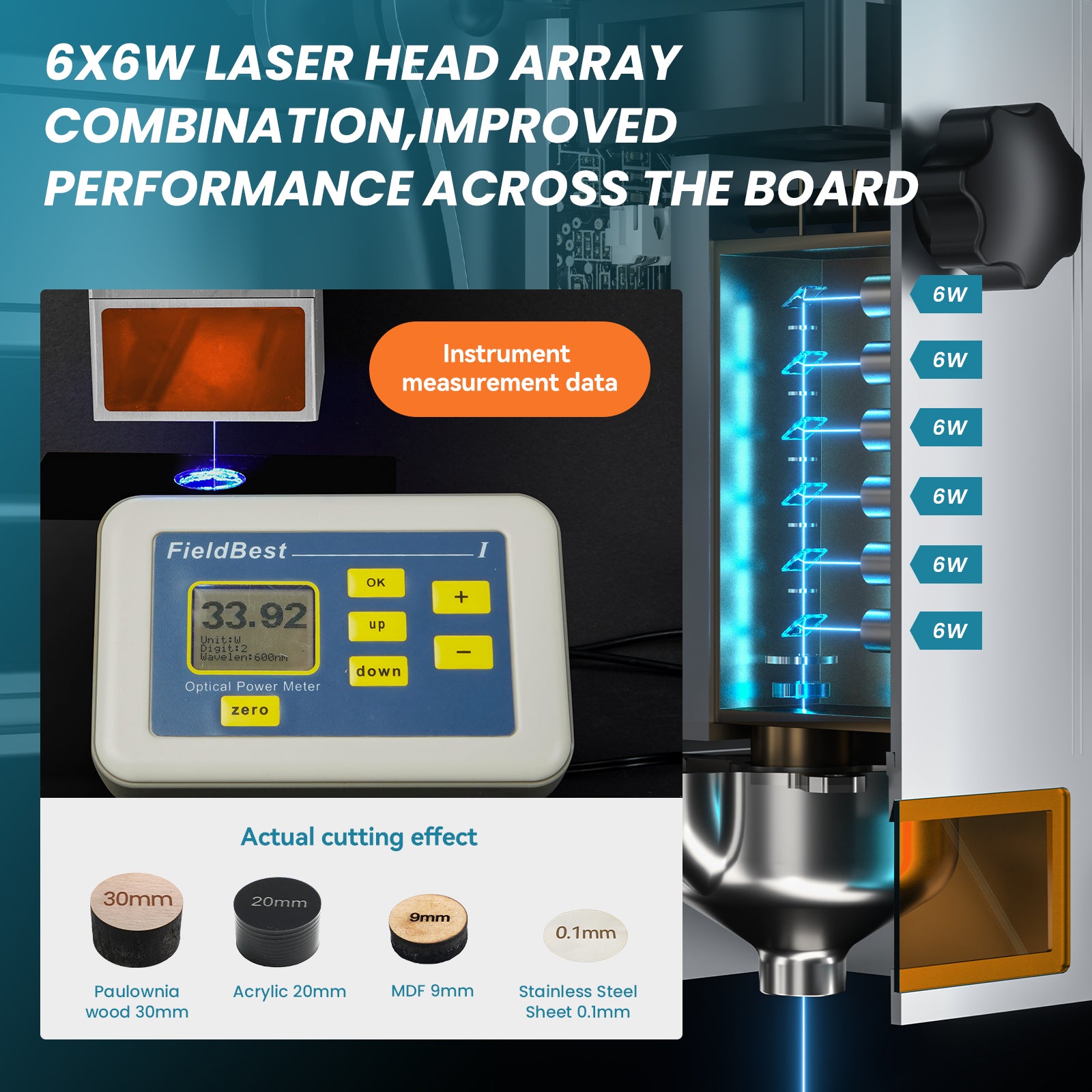

I bought this new 20-Watt laser engraving module for R&D. I took it apart and photographed it each step of the way. I put it back together after and I'll probably put it on my CNC machine at some point.

Full Album: https://ibb.co/album/nsC2tf?sort=name_asc&page=1

Full Album: https://ibb.co/album/nsC2tf?sort=name_asc&page=1

Last edited: