- Joined

- Oct 10, 2011

- Messages

- 36

- Points

- 0

Hello all

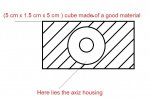

I have recently built my first 300 mw red laser , I placed it inside a hand-watch box , i ran it on 250 ma and it all worked good using only 12x30mm Aixiz laser housing , it didn't got burned as it didn't also burn as i wanted it to , so i saw that i can run it under 400 ma with a good heatsinking , so iam wondering , would a cubic heatsink (as the attached file) works well ?

, so i saw that i can run it under 400 ma with a good heatsinking , so iam wondering , would a cubic heatsink (as the attached file) works well ?

what would be the best material i can use with this heatsinking method if its any good ?

I have recently built my first 300 mw red laser , I placed it inside a hand-watch box , i ran it on 250 ma and it all worked good using only 12x30mm Aixiz laser housing , it didn't got burned as it didn't also burn as i wanted it to

what would be the best material i can use with this heatsinking method if its any good ?