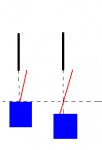

I would like to use a laser to position a work piece precisely under

the chuck of my drill press. If I were to mount the laser in the

chuck and turn it on, the laser beam would appear as a point on the

work piece that is exactly where the point of the drill would enter

when drilling.

The laser body would have to be cylindrical, not too wide (maybe 6 -

12 mm) and the beam would have to be exactly in the center of the body

for this to work.

Do you know if a laser device like this is on the market and for

a price of around $15?

Scott

the chuck of my drill press. If I were to mount the laser in the

chuck and turn it on, the laser beam would appear as a point on the

work piece that is exactly where the point of the drill would enter

when drilling.

The laser body would have to be cylindrical, not too wide (maybe 6 -

12 mm) and the beam would have to be exactly in the center of the body

for this to work.

Do you know if a laser device like this is on the market and for

a price of around $15?

Scott