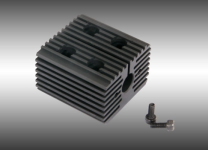

Has anyone tried to machine an aluminum heatsink with undersized bore (slightly smaller ID than the OD of the copper module for an interference fit) and cut a slot lengthwise through the aluminum heatsink to produce an open gap.

When pushing the copper module into the aluminum heatsink bore, open the gap with a large blade screwdriver, push the copper module into the center, and then pull out the screwdriver and let the tension hold the copper module in place?

This would produce greater contact all the way around the two metals when compared to a set-screw which pushes the copper module to one side of the aluminum bore.

However, it is possible that when the slot is cut, the precisely machined aluminum bore may expand or contract slightly due to the stress relief provided by the slot (internal work-hardening stresses which the aluminum heatsink rod experienced during the original cold-roll process).

When pushing the copper module into the aluminum heatsink bore, open the gap with a large blade screwdriver, push the copper module into the center, and then pull out the screwdriver and let the tension hold the copper module in place?

This would produce greater contact all the way around the two metals when compared to a set-screw which pushes the copper module to one side of the aluminum bore.

However, it is possible that when the slot is cut, the precisely machined aluminum bore may expand or contract slightly due to the stress relief provided by the slot (internal work-hardening stresses which the aluminum heatsink rod experienced during the original cold-roll process).