drlava

0

- Joined

- Mar 7, 2007

- Messages

- 1,152

- Points

- 0

Hi, it's time for the latest installment in building.. a LG ggw-h20l 6x blu-ray burner was sacrificed for its beautiful gem 405nm laser diode. This time the kenbarrel kryton was anodized in sulfuric acid using the procedure I outlined in this thread. Then the barrel was cleaned and waxed with Meguiars car wax three times to give it a smooth feel and soft shiny luster. Because of the relatively uncontrolled home anodizing process, the finish ended up with a slight pearl-like swirl finish.

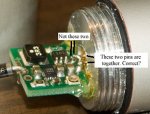

The laser diode was extracted as in the 6x thread and pressed into the kenbarrel head with a steel tube. A 1n4004 rectifier was mounted to the input of the flexdrive to drop the 6V of the 2 CR123 cells to 5.5V for the FlexDrive, and spring attached to this. The leads of the diode were stiff enough to act as a mount as long as the proper spring depth was set. The case pin of the diode was soldered to the cathode, and the pins were soldered to the FlexDrive, which was then glued in place to the barrel head, using drilled holes in the head as glue anchors. Finally, the spring was centered and the barrel assembled.

Using the provided chart, the current was adjusted to provide 85-95mW power output from the diode for long life. --EDIT: what the heck, it's not at 130mW -- A lens cap will be added for dust protection and pocket carry.

-- A lens cap will be added for dust protection and pocket carry.

So far I'm really happy with this one, and all of the parts are available so anyone else can make one too!

EDIT: added pics:

The finish has evened out and become more silver over time. It's really smooth after waxing:

The laser diode was extracted as in the 6x thread and pressed into the kenbarrel head with a steel tube. A 1n4004 rectifier was mounted to the input of the flexdrive to drop the 6V of the 2 CR123 cells to 5.5V for the FlexDrive, and spring attached to this. The leads of the diode were stiff enough to act as a mount as long as the proper spring depth was set. The case pin of the diode was soldered to the cathode, and the pins were soldered to the FlexDrive, which was then glued in place to the barrel head, using drilled holes in the head as glue anchors. Finally, the spring was centered and the barrel assembled.

Using the provided chart, the current was adjusted to provide 85-95mW power output from the diode for long life. --EDIT: what the heck, it's not at 130mW

So far I'm really happy with this one, and all of the parts are available so anyone else can make one too!

EDIT: added pics:

The finish has evened out and become more silver over time. It's really smooth after waxing: