- Joined

- Dec 2, 2008

- Messages

- 351

- Points

- 28

Hi guys, i just want to share my latest build that is not your usual one.

I have access to lot of tools as my father have them all, but one thing i am missing is lathe. Ability to shave metal with lathe is what i miss to make builds like yours from scratch. Especialy heatsinks, and be able to fit them into whatever flashlight host available.

So i was thinking how could i implement standard cubicle heatsink into working handheld laser project..

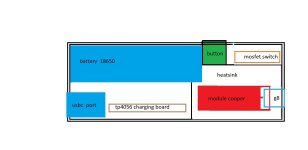

It all started with measuring and ordering components, and finding host to accomodate all of them. Sketch was needed to ensure everything will fit.

what is not shown on the sketch is ability to see battery level on the side of the host. small board with battery status leds while button is pressed was added.

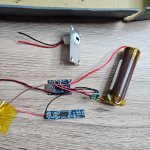

Also charging indicator leds were removed from TP charging board, and moved to the place where i wanted them, as you can see on the picture.

lens is G8 which barely holds in place, maybe half the turn, its ridiculous.. beside teflon tape on the threads i also squished silicone wire between lens and heatsink to make it hold (red thing around lens). easy, and perfect solution, its tight now.

I have access to lot of tools as my father have them all, but one thing i am missing is lathe. Ability to shave metal with lathe is what i miss to make builds like yours from scratch. Especialy heatsinks, and be able to fit them into whatever flashlight host available.

So i was thinking how could i implement standard cubicle heatsink into working handheld laser project..

It all started with measuring and ordering components, and finding host to accomodate all of them. Sketch was needed to ensure everything will fit.

what is not shown on the sketch is ability to see battery level on the side of the host. small board with battery status leds while button is pressed was added.

Also charging indicator leds were removed from TP charging board, and moved to the place where i wanted them, as you can see on the picture.

lens is G8 which barely holds in place, maybe half the turn, its ridiculous.. beside teflon tape on the threads i also squished silicone wire between lens and heatsink to make it hold (red thing around lens). easy, and perfect solution, its tight now.

Attachments

-

forum laser.jpg53.1 KB · Views: 8

forum laser.jpg53.1 KB · Views: 8 -

20240925_084033.jpg1.6 MB · Views: 9

20240925_084033.jpg1.6 MB · Views: 9 -

20240926_084832.jpg1.4 MB · Views: 9

20240926_084832.jpg1.4 MB · Views: 9 -

20240926_085345.jpg1.9 MB · Views: 6

20240926_085345.jpg1.9 MB · Views: 6 -

20240926_085202.jpg1.3 MB · Views: 7

20240926_085202.jpg1.3 MB · Views: 7 -

20240926_100002.jpg1.3 MB · Views: 6

20240926_100002.jpg1.3 MB · Views: 6 -

20240926_100112 (1).jpg1.6 MB · Views: 7

20240926_100112 (1).jpg1.6 MB · Views: 7 -

20240926_101007.jpg1.3 MB · Views: 6

20240926_101007.jpg1.3 MB · Views: 6 -

20240926_085152.jpg1.4 MB · Views: 6

20240926_085152.jpg1.4 MB · Views: 6

Last edited: