- Joined

- Sep 20, 2016

- Messages

- 8

- Points

- 0

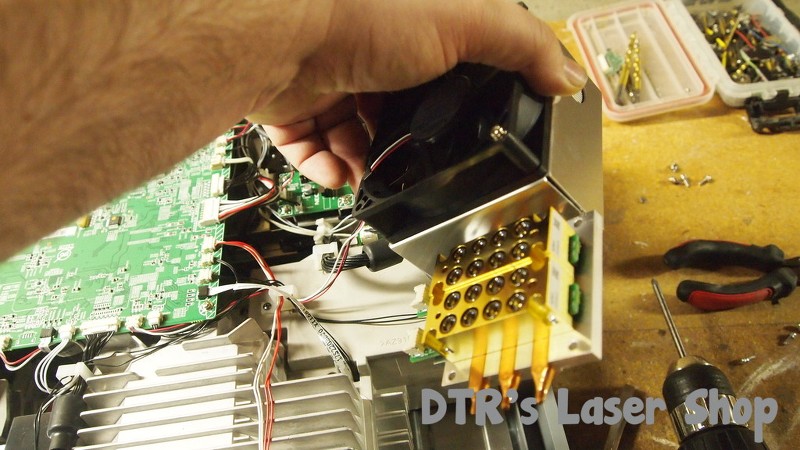

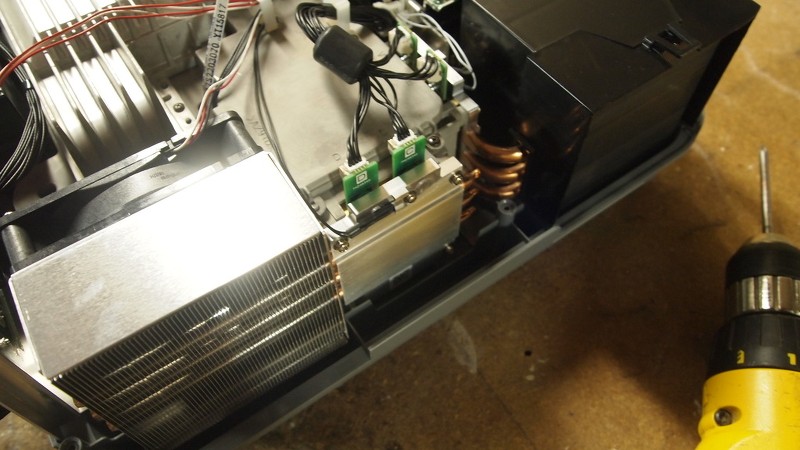

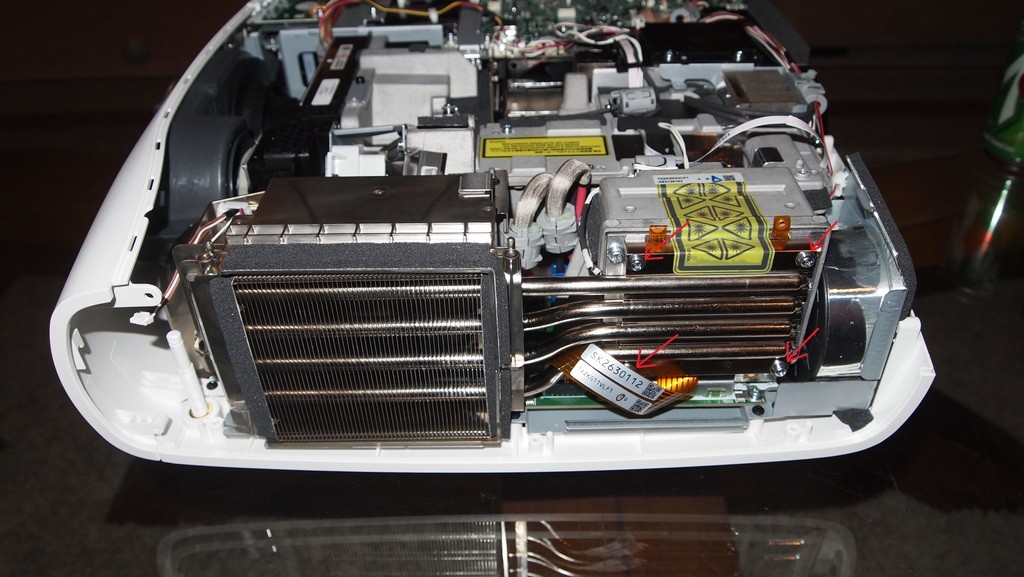

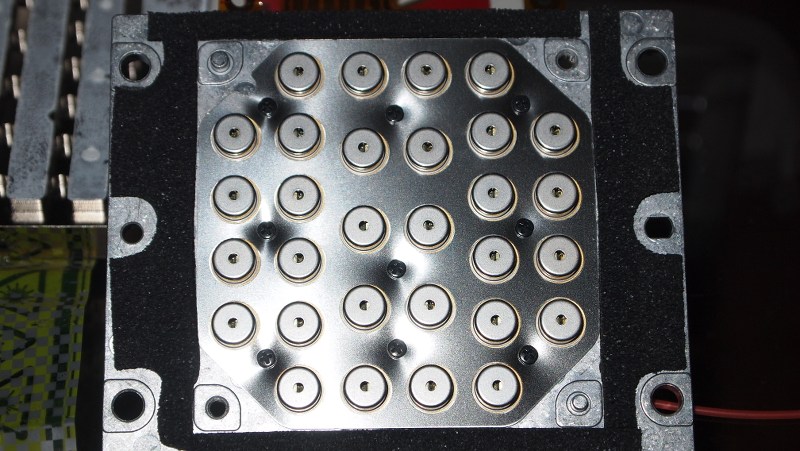

I have a set of two NUBM08 arrays (4x2 diodes each) that I would like to use as a source for a high power projector application (in a full enclosure, of course). From my reading, each diode laser array should produce a set of highly-parallel nearly collimated beams.

I know these laser diode arrays are used in projectors, and that there are commercial knife-edge mirror units with output lenses - but I don't have a good source for buying them, either new or as scrap from a teardown.

I have also considered trying to launch all of the beams into a large-core multimode fiber (1000um core or so) and I wonder if anyone has experience doing that. Can it be done with a single, large-diameter low NA lens (less than the fiber NA)? A fiber (1m-2m or so) would be convenient for coupling into the projector optics.

Anyone have some links that are helpful? Any tips or suggestions?

Thanks in advance -

I know these laser diode arrays are used in projectors, and that there are commercial knife-edge mirror units with output lenses - but I don't have a good source for buying them, either new or as scrap from a teardown.

I have also considered trying to launch all of the beams into a large-core multimode fiber (1000um core or so) and I wonder if anyone has experience doing that. Can it be done with a single, large-diameter low NA lens (less than the fiber NA)? A fiber (1m-2m or so) would be convenient for coupling into the projector optics.

Anyone have some links that are helpful? Any tips or suggestions?

Thanks in advance -

Last edited: