- Joined

- Aug 25, 2010

- Messages

- 533

- Points

- 63

This new project allow to save and reuse aluminum body and sticks.

Please NEVER launch those kind of rockets near buildings and properties: the falling mass is noticeable and dangerous.

Open spaces like grass fields without trees is the best place to launch these beasts: You can rescue the undamaged debris stuck in the ground

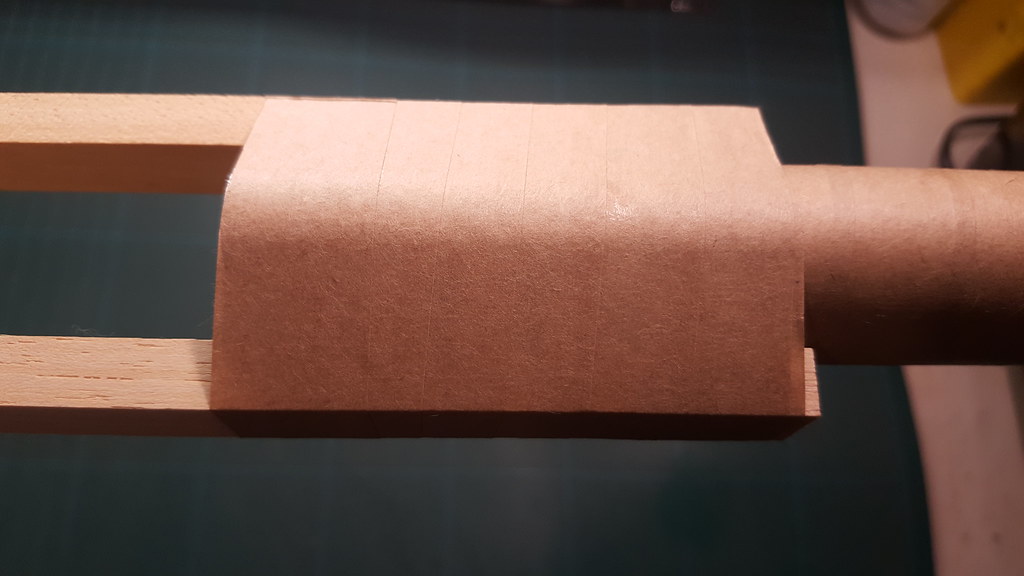

The 300mm, 1.5mm thickness aluminum tube:

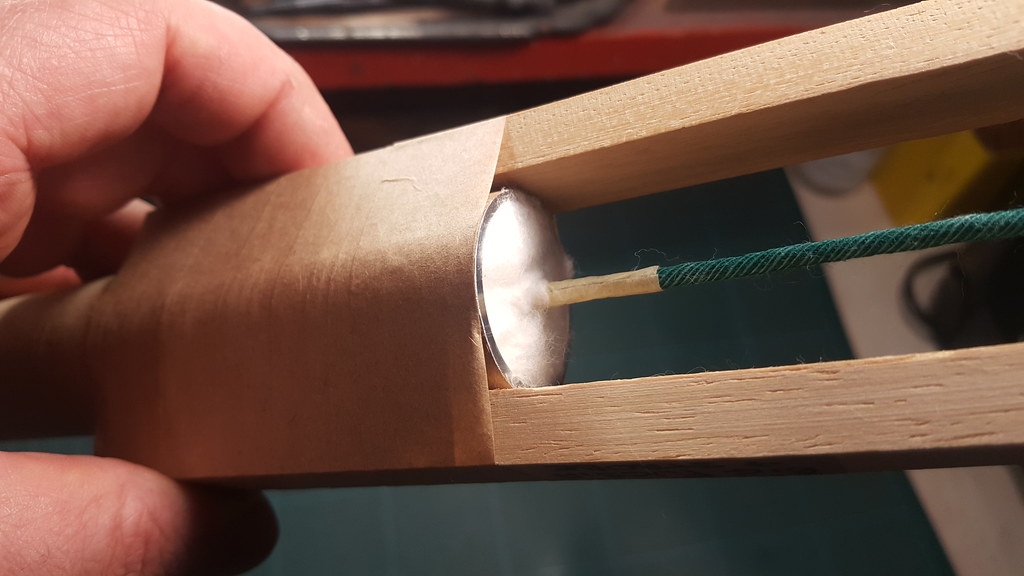

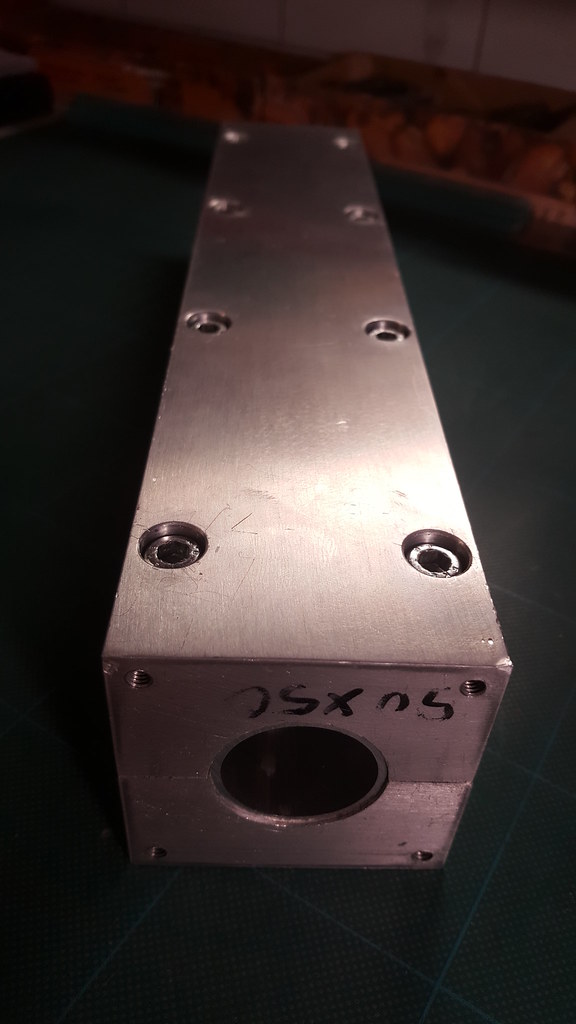

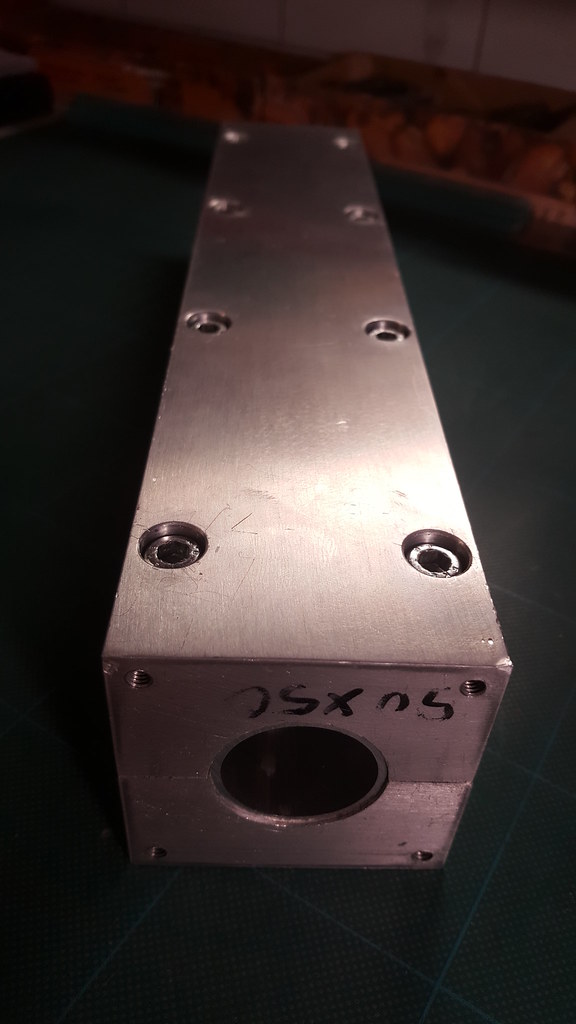

My awesome custom tube support:

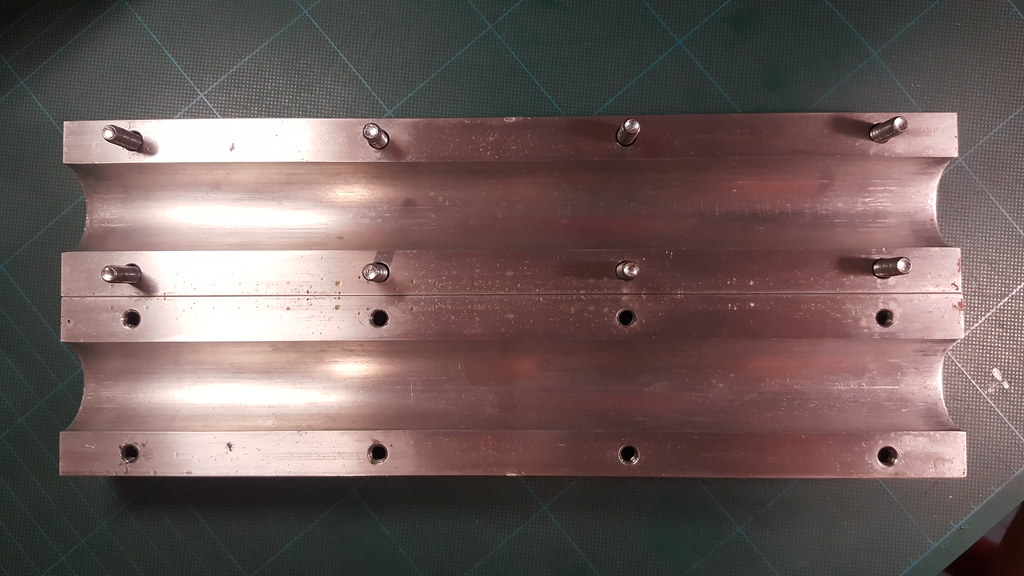

Tube inserted and firmly locked, threaded holes created for a special add-on:

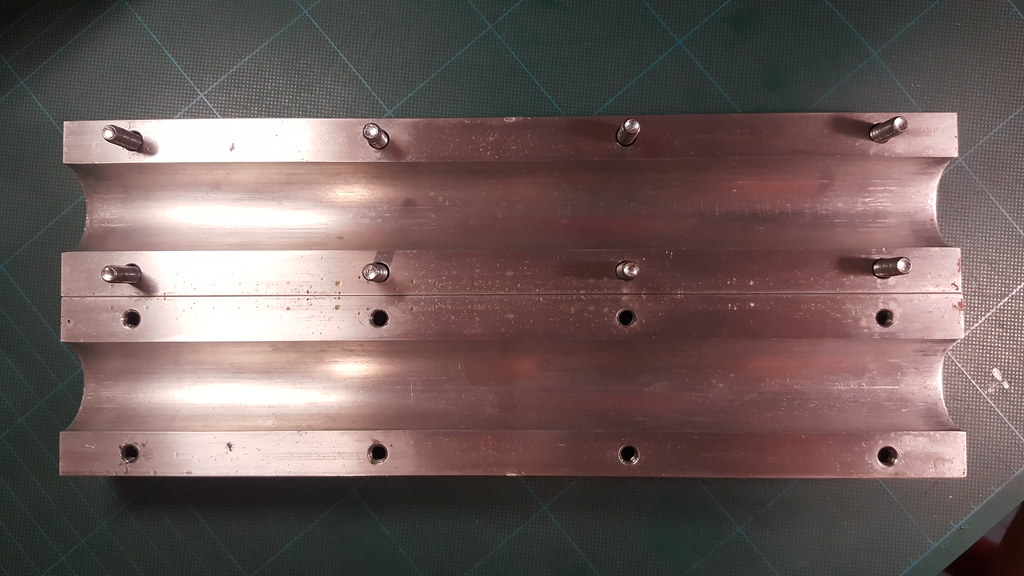

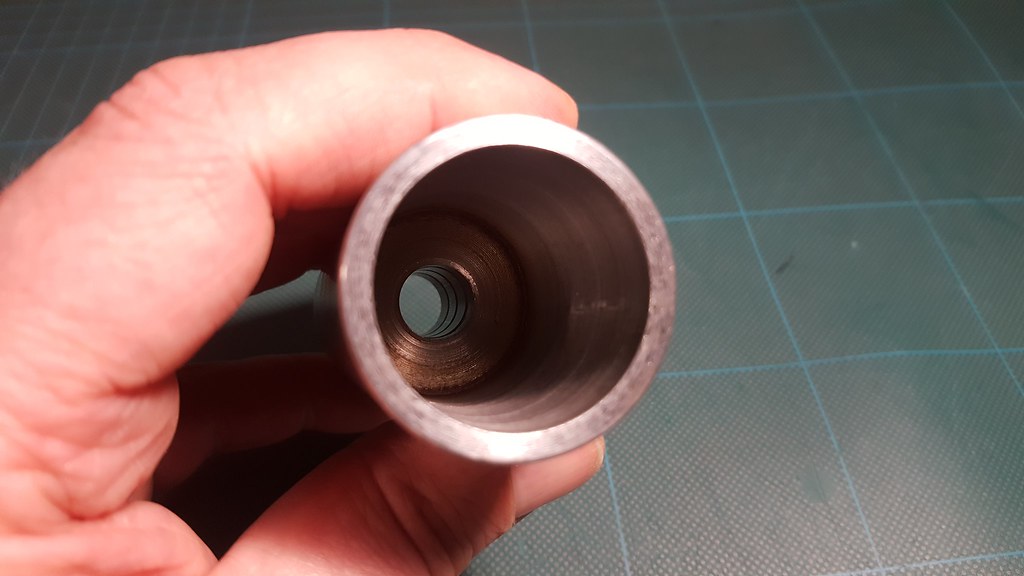

I created an extra tool, a sort of add-on, that make an useful nice recess and avoid unwanted tube sliding:

Add-on mounted:

Slightly wetted granulated r-candy mix:

(You can find my full own procedure here):

I used 70% demineralized water and 30% ethyl alcohol to facilitate the drying procedure. Few sprays of this mix should be enough.

Mix well the compond until it looks homogeneous. Do not wet too much or there will be issues during drying procedure.

A tea-spoon full of mix is the right mix quantity for every pressing step:

Starting to press the mix:

The pressure applied is very high, about 5 tons (with my rammers diameter is equivalent to 8380 PSI):

I haven't noticed any performance boost exceeding this pressure. Besides this, I encountered difficult to extract the rammers

from the tube, so I do not suggest to exceed this limit.

The last press:

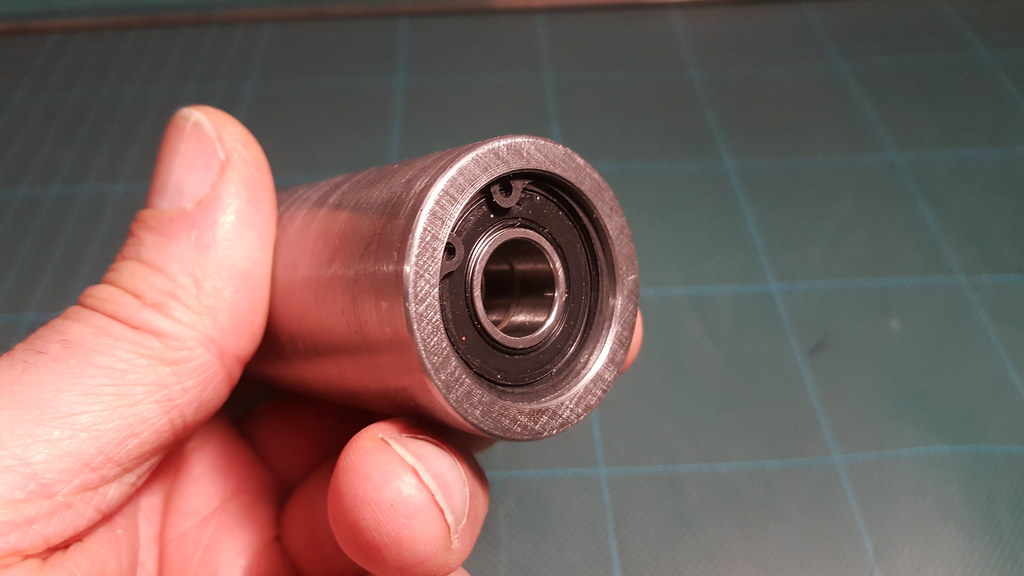

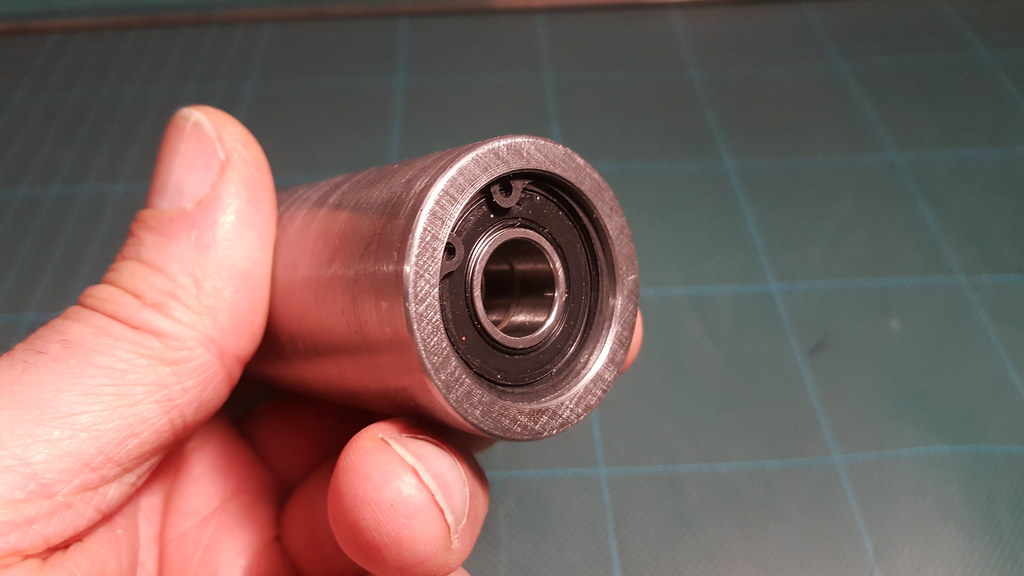

I created this special tool to make perfectly centered and parallel holes into the mix. Ball bearings was used to eliminate friction and wearings:

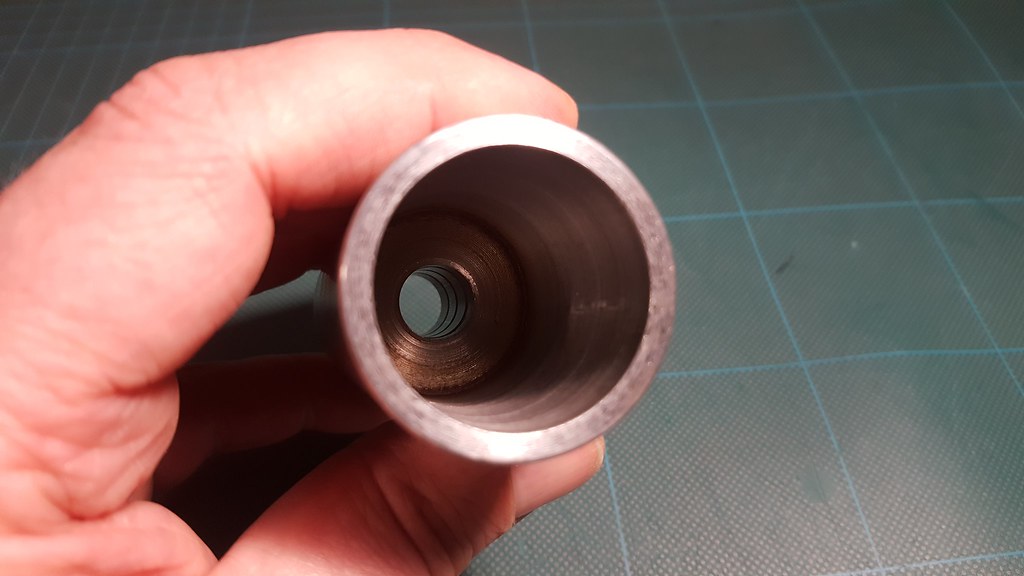

Aluminum tube inserted with perfect fit:

Drilling the hole with a 12mm drill-bit:

Please make sessions of max 2cm by time to avoid overheating the drill bit and allow the mix to come out.

I drilled tons of holes and I never had accidental mix ignitions, also in presence of titanium and with the drill bit really overheated, so it is a safe operation.

The ideal hole depth is 260mm to bring a 1300 grams shell to the right altitude.

Since these are conservative settings, You can add some extra thrust extending the tube lenght up to 350mm and extend the hole depth up to 310mm.

This extra lenght is useful for heavy double-petalled shells that weight up to 1600 grams

Hole drilled and pseudo-nozzle created with the help af a conical cutter:

Please do not waste the drilled mix: force it through a 20mesh sieve and add the powder to the classical granulated mix.

Since it is a very reactive mix, it can add a sort of boost to the original r-candy mix:

Drying the rocket with the help of a drying machine. Set the temperature at 70°C (158°F) and leave the rocket inside for an hour.

Leave the rocket cool down (beware, the aluminum tube will be really hot!), re-drill the hole and put again the rocket inside the dryer for another hour.

Why? Well, the aluminum tube will not absorb the humidity, so a sort of r-candy syrup will escapes inside the hole and thru the hole, shrinking

a little bit the hole diameter. Re-drilling the hole will restore the original diameter (and You will earn some extra wetted mix, LOL).

Please NEVER launch those kind of rockets near buildings and properties: the falling mass is noticeable and dangerous.

Open spaces like grass fields without trees is the best place to launch these beasts: You can rescue the undamaged debris stuck in the ground

The 300mm, 1.5mm thickness aluminum tube:

My awesome custom tube support:

Tube inserted and firmly locked, threaded holes created for a special add-on:

I created an extra tool, a sort of add-on, that make an useful nice recess and avoid unwanted tube sliding:

Add-on mounted:

Slightly wetted granulated r-candy mix:

(You can find my full own procedure here):

How to make hot granulated r-candy mix

Hello forum. As promised some weeks ago here is the first chapter of a complete tutorial how to make perfect r-candy powered fireworks. I switched to the granulated version for many reasons, and I'm very happy of my choice and for the good results. This is the first of many tutorials, and every...

laserpointerforums.com

I used 70% demineralized water and 30% ethyl alcohol to facilitate the drying procedure. Few sprays of this mix should be enough.

Mix well the compond until it looks homogeneous. Do not wet too much or there will be issues during drying procedure.

A tea-spoon full of mix is the right mix quantity for every pressing step:

Starting to press the mix:

The pressure applied is very high, about 5 tons (with my rammers diameter is equivalent to 8380 PSI):

I haven't noticed any performance boost exceeding this pressure. Besides this, I encountered difficult to extract the rammers

from the tube, so I do not suggest to exceed this limit.

The last press:

I created this special tool to make perfectly centered and parallel holes into the mix. Ball bearings was used to eliminate friction and wearings:

Aluminum tube inserted with perfect fit:

Drilling the hole with a 12mm drill-bit:

Please make sessions of max 2cm by time to avoid overheating the drill bit and allow the mix to come out.

I drilled tons of holes and I never had accidental mix ignitions, also in presence of titanium and with the drill bit really overheated, so it is a safe operation.

The ideal hole depth is 260mm to bring a 1300 grams shell to the right altitude.

Since these are conservative settings, You can add some extra thrust extending the tube lenght up to 350mm and extend the hole depth up to 310mm.

This extra lenght is useful for heavy double-petalled shells that weight up to 1600 grams

Hole drilled and pseudo-nozzle created with the help af a conical cutter:

Please do not waste the drilled mix: force it through a 20mesh sieve and add the powder to the classical granulated mix.

Since it is a very reactive mix, it can add a sort of boost to the original r-candy mix:

Drying the rocket with the help of a drying machine. Set the temperature at 70°C (158°F) and leave the rocket inside for an hour.

Leave the rocket cool down (beware, the aluminum tube will be really hot!), re-drill the hole and put again the rocket inside the dryer for another hour.

Why? Well, the aluminum tube will not absorb the humidity, so a sort of r-candy syrup will escapes inside the hole and thru the hole, shrinking

a little bit the hole diameter. Re-drilling the hole will restore the original diameter (and You will earn some extra wetted mix, LOL).

Last edited: