Borislav@87

Active member

- Joined

- Mar 20, 2022

- Messages

- 434

- Points

- 43

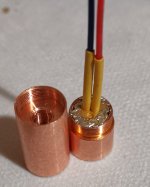

Hello. I'm posting a separate topic here if anyone has a similar problem. I bought a G8 lens for my custom laser, but the lens barely held because it made a good spot at just one turn of the thread. She was swaying and would fall at any moment. What did I do in this case. I disassembled the lens. I removed the glass and before that I turned the glass clamp first. So the glass is already somewhere in the middle of the body. I disassembled a 3-element lens because I have several. I took the clamp, put it in the body of the G8 and tightened the glass with it. The glass is pressed between the two clamps and I already use 60-70% of the thread until the best stain is formed. I used tweezers for the glass and did not touch it. You will need a suitable width to develop the clamps. I am very glad that everything turned out perfectly!

Attachments

-

Screenshot_20220328_193034_com.android.gallery3d_edit_58402748628067.jpg201.8 KB · Views: 15

Screenshot_20220328_193034_com.android.gallery3d_edit_58402748628067.jpg201.8 KB · Views: 15 -

1648485496519_edit_58848071734249.png960 KB · Views: 12

1648485496519_edit_58848071734249.png960 KB · Views: 12 -

Screenshot_20220328_193039_com.android.gallery3d_edit_58395436959839.jpg316.8 KB · Views: 12

Screenshot_20220328_193039_com.android.gallery3d_edit_58395436959839.jpg316.8 KB · Views: 12 -

Screenshot_20220328_163210_com.ebay.mobile.jpg687.3 KB · Views: 14

Screenshot_20220328_163210_com.ebay.mobile.jpg687.3 KB · Views: 14 -

IMG_20220328_200138.jpg705.8 KB · Views: 14

IMG_20220328_200138.jpg705.8 KB · Views: 14