Hi Im still building

You need a 16.8 mm contact board. Although its expensive you can get one from

Survival lasers. As you mentioned

FP might still have some, or failing that you could try

Marcuspeh.

One other option would be to try DX, Fasttech, Kaidomain, Banggood and Gearbest.

I will try to find a link to something suitable.

Last resort would be to strip the components from a cheap 16.8 - 17 mm flashlight driver or to cut one out yourself from a piece of PCB. In the case of the later you can just put a screw through the middle of the board to act as the positive contact. Heres an example of a groove contact board mod from Kenom

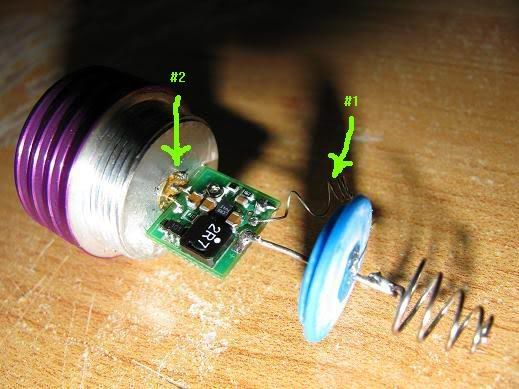

This is a picture of one of the contact boards I used in my builds (now sold out at

Intl-outdoor unfortunately) and a picture of the inside of the host with the board installed. Interestingly Intl-outdoor ran out of these boards around the time Marcuspeh started selling them.

Solder the board (as above) with a spring and leads first and use 2 part epoxy around the edge of the underside of the board, side where the spring is, and carefully lower it into the tube until it reachs the inside lip. Push the board down firmly into place and make sure the positive wire is not touching the inside. Take a 1.25 mm drill bit and drill a hole next to the negative contact pad through the board and lip of the host. Use a 1.3 mm brass nail and hammer it through the board and lip - helps if you pre-solder the head of the nail first. Once the nail is in place and touching the negative pad, cut a small strip of solder and drop it into the hole on top of the nail and next to the negative pad. Holding the wires out of the way, take a big soldering iron head and touch it to the nail head and board. The solder will flow and make contact. Take care here not to desolder the negative wire ie hold it well in place and be quick. If you turn the laser over and look in the battery compartment you will see the nail poking through, this needs to be bent over with ie a screwdriver and hammered down against the lip - dont let it touch the spring! Doing this has two purposes; one it reinforces the board to host physical connection and secondly it will allow the battery to make contact with the spring - it cant if the nail is in the way!

If you need any further help just let me know, Ill also try to dig out some more pics of the process.:beer: