we all know dvd burner lasers well the strength and class are fairly easy to source decent quality lasers, some people have made laser etchers even ones that can burn into wood a bit, but there are 3 things here that are factors,

#1 power limit (those diodes run at about 200 to 250mW max

#2 shape and beam size, (most of those lasers create a rectangular beam)

#3 conical cut ( using a convex lens even a high quality one out of a laser printer creates a beam focused slightly below the surface and then it diverges again beyond the focal point.

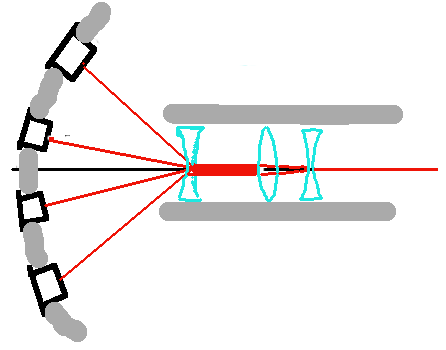

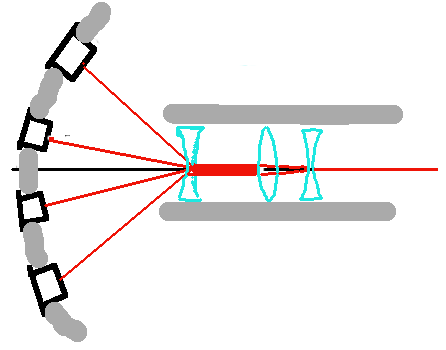

so I had an idea use more than one of these lasers, the number has really no theoretical limit as long as long as the directionality directed in the right way and cooling is applied properly.

the lenses might also need to be cooled through an aluminum heatsink/ lens holder focus tube.

here is a picture

I dunno if this could work but I would like to hear some ideas, also I dunno but even one laser may benefit form a 2 lens convex the concave combo if focused right. I mean the smaller and more parallel the beam is when it hits the cutting surface the better

terramir

#1 power limit (those diodes run at about 200 to 250mW max

#2 shape and beam size, (most of those lasers create a rectangular beam)

#3 conical cut ( using a convex lens even a high quality one out of a laser printer creates a beam focused slightly below the surface and then it diverges again beyond the focal point.

so I had an idea use more than one of these lasers, the number has really no theoretical limit as long as long as the directionality directed in the right way and cooling is applied properly.

the lenses might also need to be cooled through an aluminum heatsink/ lens holder focus tube.

here is a picture

I dunno if this could work but I would like to hear some ideas, also I dunno but even one laser may benefit form a 2 lens convex the concave combo if focused right. I mean the smaller and more parallel the beam is when it hits the cutting surface the better

terramir

Last edited: