- Joined

- Mar 24, 2015

- Messages

- 7

- Points

- 0

I have an M140 (A type) as part of a homemade CNC build. It is now shining dimly, which I’ve read is a sign that its lasing days are over. I’d like to detail my whole setup and the events leading up to its failure in an effort to find out how to not kill any more diodes.

Here’s my setup:

• M140 type A diode from DTR (copper module, standard glass lens)

• Heatsink is a simple aluminum mount from Aixiz. The driver also has an overheat protection freature with a thermal sensor that I affixed to the diode heatsink

• Driver: Simpledrive I from X-Wossee. I got it because I wanted adjustable current output and PWM input (also it was recommended on DTR’s CNC page). I’ve been very happy with it overall.

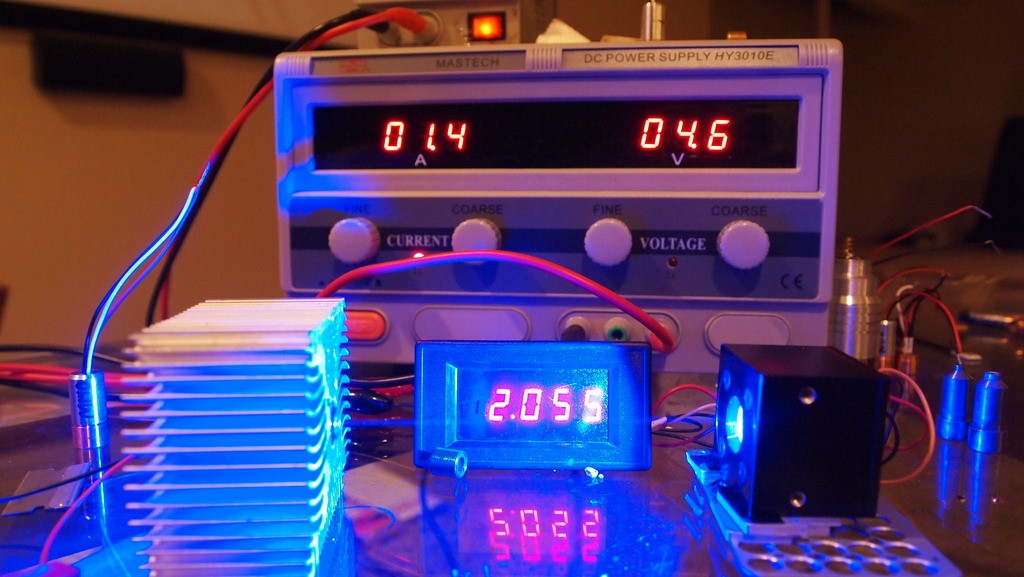

• Test load: Homemade string of 6 1N5408 diodes (0.8v drop from each totaling a voltage drop of 4.8v to compare to an expected drop from the M140 of 4.7v)

• Input power supply: an old laptop power supply: 2A @ 12V

• PWM source for driver activation: 4.8v from arduino

Here’s what happened:

I initially set the driver’s gain current using my test load to 0.8A. After about a day of happy lasing, I realized I was demanding a lot of power dissipation from the driver (24W in, 3.4W out), so I again used the test load to set the driver to 1.45A. Still no problem: it worked for several hours after this. During this time, I was tweaking the software for the CNC machine so I was switching the driver power on and off as I test gcode commands. I don’t believe this was was a rough duty cycle (probably 30s on to 1min off); the heatsink didn’t feel warm at all. At some point, without any incident that I can recall, I switched on the diode to see it shining very dimly.

I’m baffled by how sudden this was; I can’t think of any event that would have caused it to fail. If you can provide any insight into ways a diode can die and what I can do to make that not happen in the future, I would really appreciate it. If you want more pictures or info, I’ll be happy to provide it.

Here is an album with pictures of my setup as well as before and after photos of the laser:

Click Here!

Here’s my setup:

• M140 type A diode from DTR (copper module, standard glass lens)

• Heatsink is a simple aluminum mount from Aixiz. The driver also has an overheat protection freature with a thermal sensor that I affixed to the diode heatsink

• Driver: Simpledrive I from X-Wossee. I got it because I wanted adjustable current output and PWM input (also it was recommended on DTR’s CNC page). I’ve been very happy with it overall.

• Test load: Homemade string of 6 1N5408 diodes (0.8v drop from each totaling a voltage drop of 4.8v to compare to an expected drop from the M140 of 4.7v)

• Input power supply: an old laptop power supply: 2A @ 12V

• PWM source for driver activation: 4.8v from arduino

Here’s what happened:

I initially set the driver’s gain current using my test load to 0.8A. After about a day of happy lasing, I realized I was demanding a lot of power dissipation from the driver (24W in, 3.4W out), so I again used the test load to set the driver to 1.45A. Still no problem: it worked for several hours after this. During this time, I was tweaking the software for the CNC machine so I was switching the driver power on and off as I test gcode commands. I don’t believe this was was a rough duty cycle (probably 30s on to 1min off); the heatsink didn’t feel warm at all. At some point, without any incident that I can recall, I switched on the diode to see it shining very dimly.

I’m baffled by how sudden this was; I can’t think of any event that would have caused it to fail. If you can provide any insight into ways a diode can die and what I can do to make that not happen in the future, I would really appreciate it. If you want more pictures or info, I’ll be happy to provide it.

Here is an album with pictures of my setup as well as before and after photos of the laser:

Click Here!

Last edited: