Maybe this overview will help members understand the situation and technical circumstances with greater clarity.

The reason that correction of slow and fast axis divergence is uncommon in hand held portable lasers and is not part of ordinary laser pointer manufacturing/production is because they are designed to be as cheap/low cost as possible for pointing or demonstration, better beam quality does not matter/ is not necessary for any envisioned applications. There is little if any but a small niche market for something better and the nature of low cost mass produced laser diodes never designed or meant tor inclusion in handheld laser pointers which is way too small a market justify mass production of laser diodes, the market and purpose for laser diodes being generally commercial video projector manufacturers with the goal of making them at lowest cost possible at whatever quality and cost point the manufacturer wants to target for large scale distribution and sales.

Keep in mind the first relatively low cost laser diode pointer production were the Wicked Lasers Spyder III Arctic pointers made from Ca$$io projector diodes. Everything that came after was essentially a "me too" product to make $s in a growing demand for pointers fueled by clever marketing and videos on TY and so on. Their purpose in the real world was what? Create an interesting toy with a Star Wars light saber look to pop balloons and light matches and make a bright beam marketed to an enthusiastic base at a relatively affordable price compared to earlier iterations costing thousands of dollars using DPSS lasers and having better beam quality. Certainly, not to be laboratory quality research lasers.

Bottom line is $$$ and that " you can't make a silk purse out of a sow's ear" for the low disposable income level customer which the majority of the largest potential customer base with only X to spend are combined with that they have no real reason.need to own a laser of any kind to begin with.

A laser pointer was an affordable advanced curiosity/cool novelty thingy from the outset marketed by captuing the imagination of thousands of customers and potential customers as something new and different, "lightsaber" like, and also dangerous even better.

The market base for pointers, generally, just wants cheap and makes a visible light beam so....

The enthusiast and hobbyist laser market people can dress it up to make it look a bit better and have the $$$ to spend doing so and better quality optics for doing just that are available.

Better than pointer quality, better beam quality diode lasers with a divergence <1.5 mrad and even < 1 mrad are made, marketed, and sold as lower cost lab units at prices much higher than any pointers due to housing costs, optical components, adjustments /set-up needed, power supply, and testing costs necessary to produce same.

Examples are CNI's range d diode lasers --see:

https://www.ultralasers.com/lasers-series.php?cat=42

"Broad area laser diodes (also called

broad stripe or

broad emitter laser diodes,

single-emitter laser diodes, and

high brightness diode lasers) are

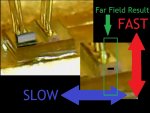

edge-emitting laser diodes where the emitting region at the front facet has the shape of a broad stripe, with dimensions of e.g. 1 μm × 100 μm. Due to the asymmetry of the emitter, the beam properties are also completely different for the two directions:

- In the vertical (short) direction, the height (e.g. 1 μm) is small enough to obtain single-mode guidance and thus an essentially diffraction-limited beam quality with an M2 factor only slightly above 1. Because of the small aperture size, the beam divergence in this direction is relatively high, with a beam divergence half-angle of e.g. 370 mrad, corresponding to an FWHM angular range of 25°. Due to that fast divergence, this is called the fast axis direction.

- In the long direction (slow axis direction), the stripe width may be e.g. 50, 100, 200 μm, or even larger, so that the light is distributed over many spatial modes in this direction. As a result, the beam divergence is much larger than for a diffraction-limited beam with that size, although still significantly smaller than for the fast axis direction. (Typical values are around 5–10° FWHM.) The beam quality in terms of focusability is reduced; M2 might be of the order of e.g. 20 for a 100-μm stripe. Furthermore, the beam profile may be multi-peaked in the horizontal direction, and the shape of the intensity pattern may depend on the injection current.

The

wavefronts at the output facet are approximately plane in horizontal and vertical direction, but there can be some

astigmatism, i.e., a slightly different focus position for the two directions."

"The strongly asymmetric beam profile and the large divergence in the “fast” direction requires special care, e.g. for properly

collimating the output of a broad area laser. A common method is the use of a cylindrical “

fast axis collimator”

lens with high

numerical aperture in close proximity to the diode facet. Such a lens collimates the beam in the fast axis direction, before the beam radius becomes too large. A second cylindrical

lens at a larger distance may then be used for collimation in the slow axis direction. By choosing lenses with suitable

focal lengths, a circular beam can be obtained, which however will have different divergence angles in the two directions due to the different beam quality values. "

The above from:

https://www.rp-photonics.com/broad_area_laser_diodes.html

"Collimators for Single-emitter Laser Diodes"

"Asymmetric beams are typical for laser diodes."

"Single-emitter laser diodes usually exhibit substantially different divergence in two orthogonal directions. In typical cases, one has about 10° divergence (full width at half maximum) in the “slow” direction and ≈30° in the “fast” direction. On the other hand, the focus positions are often very close together (very small

astigmatism) at least for so-called index-guided laser diodes, so that an ordinary lens (not a

cylindrical one) placed at an appropriate distance to the laser diode output can simultaneously collimate light in both directions. Only, the

beam radius in the two directions will be substantially different; it may for example be about three times larger in the “fast” direction.

In many cases, it is required to transform the beam profile into a circular one; this is often accomplished by applying an

anamorphic prism pair, which may either be used separately or integrated into a laser diode collimator device. Alternatively, one may use two

cylindrical lenses, each one having a

focal length which is appropriate for obtaining the desired beam radius in its direction. Another technical option is a cylindrical

microlens mounted with high precision close to the laser diode facet for transforming the beam into a circular one."

"Astigmatism makes it more difficult to produce a circular beam."

"For gain-guided laser diodes (typically those with higher output powers), there is the additional problem of

astigmatism: the focus positions for the two directions do not exactly coincide. Although their distance is small compared with the length of the laser diode chip, it is substantial when comparing with the

Rayleigh length. A consequence of that is that slightly different lens positions (distances to the output facet of the laser diode) would be required for perfect collimation in the two directions. Although an anamorphic prism pair can still be used for producing and approximately circular beam, the astigmatism cannot be corrected that way.

A pair of cylindrical lenses, which can be independently adjusted, can be a good solution.

Strictly speaking, the used cylindrical lenses often have

acylindrical surfaces, i.e., some deviations from the cylindrical shape such as to minimize aberrations (see the article on

aspheric optics)."

The above from:

https://www.rp-photonics.com/laser_diode_collimators.html

www.rp-photonics.com