Hello everybody,

I try to build laser driver for my laser engraver with a dvd burner.

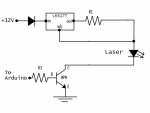

I made this following plan:

i chose red laser from dvd burner with 320mA therefore R1= 3,9ohm, 1watts.

After several try, the diode doesn't engrave paper... Have you got any ideas why ?

And last question, how to buy laser 650nm and 250-300mW please ?

Sorry for my bad English..

thanks all

Max

I try to build laser driver for my laser engraver with a dvd burner.

I made this following plan:

i chose red laser from dvd burner with 320mA therefore R1= 3,9ohm, 1watts.

After several try, the diode doesn't engrave paper... Have you got any ideas why ?

And last question, how to buy laser 650nm and 250-300mW please ?

Sorry for my bad English..

thanks all

Max

Attachments

Last edited: