- Joined

- Apr 26, 2010

- Messages

- 173

- Points

- 0

hello.

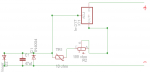

i have always wanted to try etching my own PCB.

i was wondering if i would be allowed to etch DDl drivers and sell them to mates???( do i need permission from DDl)

secondly how much does a usual etching kit cost?

cheers.

i will be visiting my dicksmith tomorrow to purchase the stuff will let you know how it goes.

cheers

p.s im australian

i have always wanted to try etching my own PCB.

i was wondering if i would be allowed to etch DDl drivers and sell them to mates???( do i need permission from DDl)

secondly how much does a usual etching kit cost?

cheers.

i will be visiting my dicksmith tomorrow to purchase the stuff will let you know how it goes.

cheers

p.s im australian