Hi everybody!

I have a Class 3b IR LED from a laser printer.

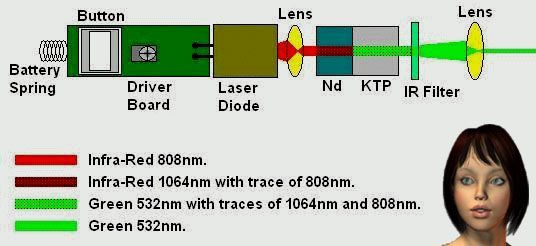

I was wondering... Can I take the dye from a cheapo class IIIa green laser pointer (<20 mW) and put it between the LED and it's lens assembly?

And would this give me a higher power green laser?

Thanks!

I have a Class 3b IR LED from a laser printer.

I was wondering... Can I take the dye from a cheapo class IIIa green laser pointer (<20 mW) and put it between the LED and it's lens assembly?

And would this give me a higher power green laser?

Thanks!