djQUAN

0

- Joined

- May 27, 2013

- Messages

- 1,154

- Points

- 63

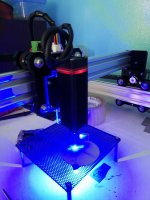

Not new to the high power blue laser game but I just got a low cost blue laser engraver for my projects. (proto pcbs, labeling enclosures, etc)

The unit I got has a laser head (black one in attached pics) rated for 5500mW optical power. Right out of the box, used my Ophir LPM, it did about 5800mW at turn on and drops to about 5600mW steady state which is a good sign and I was happy.

About 4 hours total use (testing, trials, experiments on settings), I did another LPM test and it had dropped to 5000mW.

I did another 4.5hour engraving task (A3 sized photo onto wood) at about 70% power due to it being light colored, lower powers won't touch it, max power is now at only 4600mW.

The lens appears to still be clean, I can't see any smoke residue or dirt.

Reading about cheap engravers, the common trend I see is that the diodes are over driven.

Now for the fun part: I did some quick tests, the driver pushes about 3.8A to the laser diode and looking at the diodes available on DTR's site, the 7W NUBM44 diode should push about 6.4W at 3.8A. With the 3.5W NDB7A75 overdriven at 3.8A put out a little over 5W which confirms that my diode is most probably overdriven too.

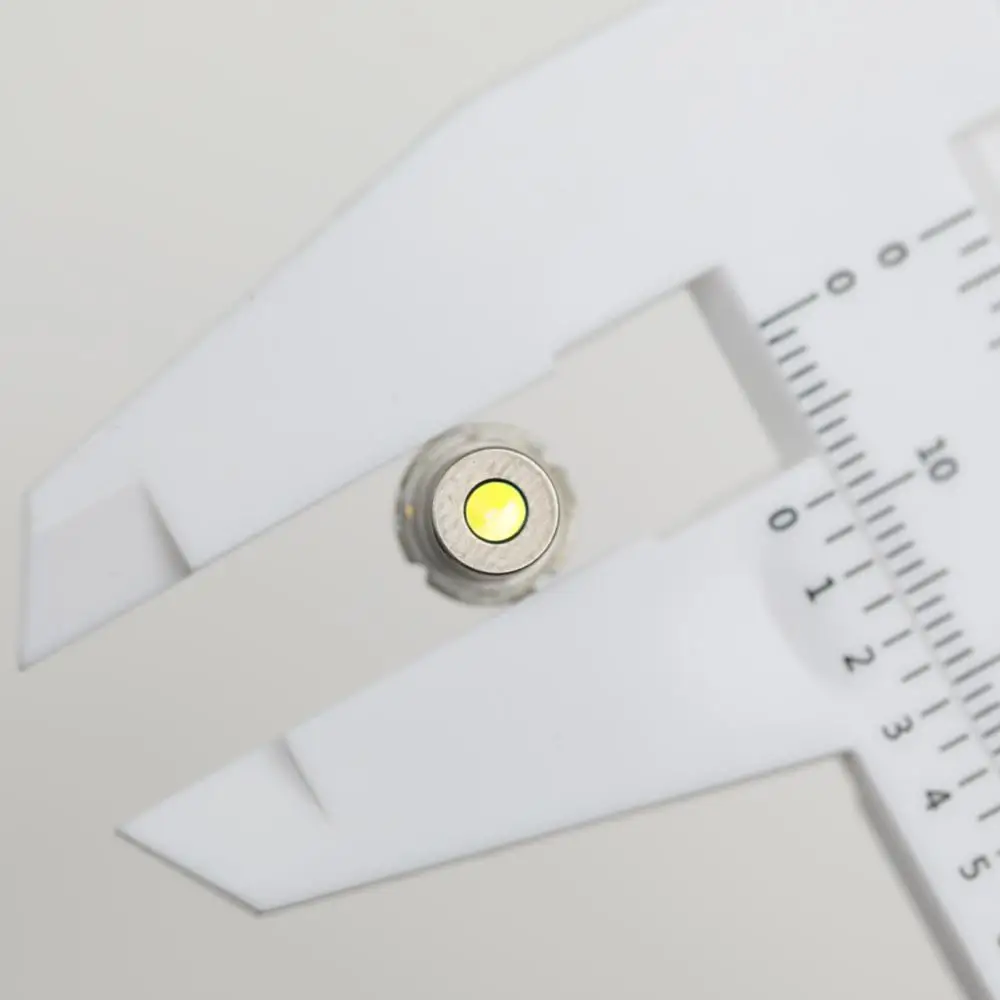

I was looking to upgrade to the blue one (image attached) which is also 5500mW but fixed focus and is said to include FAC for a better beam/spot shape but the overdriven diode concern is still there.

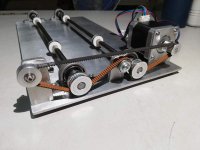

The other option I was thinking was to get the 7W diode from DTR and slap it onto the stock head for better reliability.

Price wise, the 7W bare diode will cost about the same as the complete FAC laser head with sliding mount.

Why not just keep on using it at low power? Well, I bought a high power laser I want to be able to use the full power capability. And also not worry about lifetime when I really needed the power to engrave or cut more difficult materials.

And also not worry about lifetime when I really needed the power to engrave or cut more difficult materials.

Another thing to consider is that the 7W diode has a much bigger (wider) spot so resolution might suffer a bit when engraving small texts. The FAC head should be pretty good in this regard.

Thoughts? Comments? Any help is appreciated

The unit I got has a laser head (black one in attached pics) rated for 5500mW optical power. Right out of the box, used my Ophir LPM, it did about 5800mW at turn on and drops to about 5600mW steady state which is a good sign and I was happy.

About 4 hours total use (testing, trials, experiments on settings), I did another LPM test and it had dropped to 5000mW.

I did another 4.5hour engraving task (A3 sized photo onto wood) at about 70% power due to it being light colored, lower powers won't touch it, max power is now at only 4600mW.

The lens appears to still be clean, I can't see any smoke residue or dirt.

Reading about cheap engravers, the common trend I see is that the diodes are over driven.

Now for the fun part: I did some quick tests, the driver pushes about 3.8A to the laser diode and looking at the diodes available on DTR's site, the 7W NUBM44 diode should push about 6.4W at 3.8A. With the 3.5W NDB7A75 overdriven at 3.8A put out a little over 5W which confirms that my diode is most probably overdriven too.

I was looking to upgrade to the blue one (image attached) which is also 5500mW but fixed focus and is said to include FAC for a better beam/spot shape but the overdriven diode concern is still there.

The other option I was thinking was to get the 7W diode from DTR and slap it onto the stock head for better reliability.

Price wise, the 7W bare diode will cost about the same as the complete FAC laser head with sliding mount.

Why not just keep on using it at low power? Well, I bought a high power laser I want to be able to use the full power capability.

Another thing to consider is that the 7W diode has a much bigger (wider) spot so resolution might suffer a bit when engraving small texts. The FAC head should be pretty good in this regard.

Thoughts? Comments? Any help is appreciated