I AM AT MY WITS END!!!

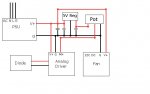

So I went digging through my stock and actually found another 445nm diode. I decided to build an "actually real" board for the modulation and put it into a "nice" housing. I also ran the fan to the PSU(this may or may not have been the NEW problem)

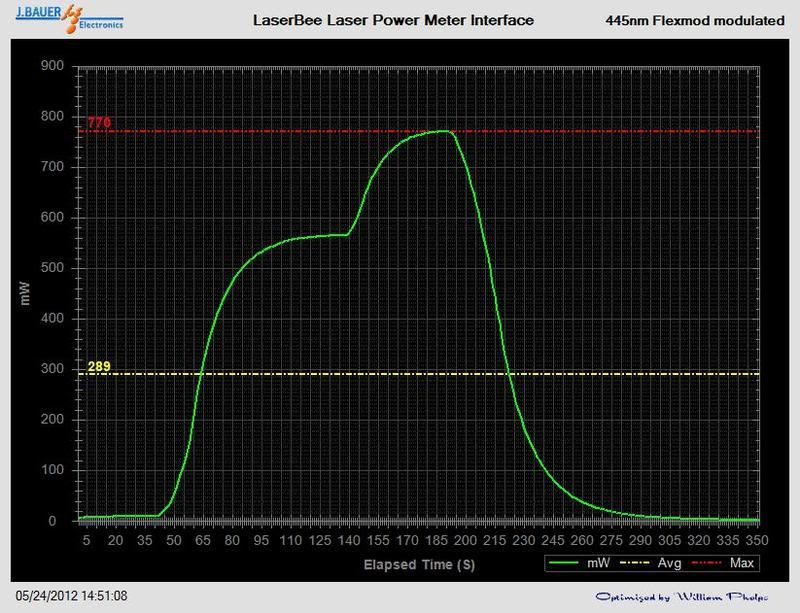

Okay, I got it all nice looking...believe it or not the modulation "board" did work perfectly when I tested it. I hooked up an on/off switch as well that worked just fine.

At first when I fired it up the driver went through its low power start up and then into the higher power setting(1.25A). Everything seemed fine but I didn't have any modulation change off the POT. After looking at it a bit closer I realized I didn't have a negative hooked up to the POT for the modulation. There happened to be an extra negative lead from one of my external hook ups that I could use so I soldered it to the POT.

Plugged the unit back in and switched it to ON. The driver cycled again and came to high power. I turned the pot and the power droped down to 0 and then turned it up again to full.

I turned it off and then turned it on again. I 'think' I may have heard a very small crack. There was no output from the laser and the red light on the driver was back on. A couple more try's and nothing....I clipped the wires to the diode and put it on the benchtop PSU and YUP....SURE ENOUGH....completely DEAD! not even an led.:cryyy:

I just don't know why this project has turned out to be such a huge problem but i'm setting it aside until I can really know what the hell is going on!

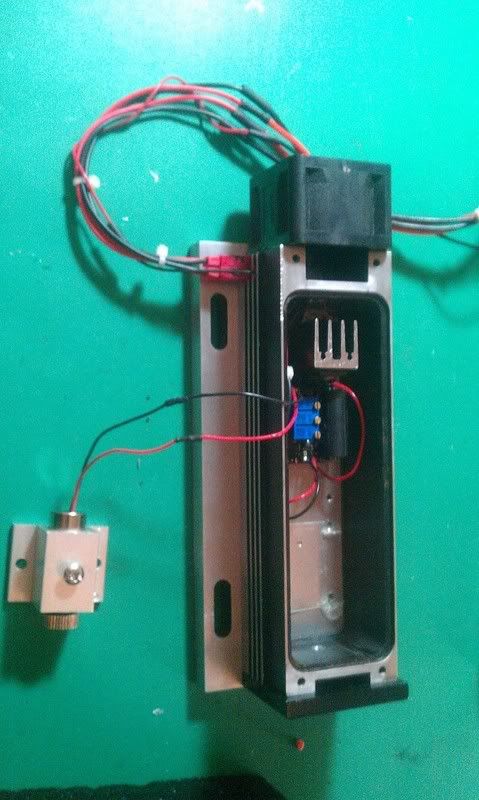

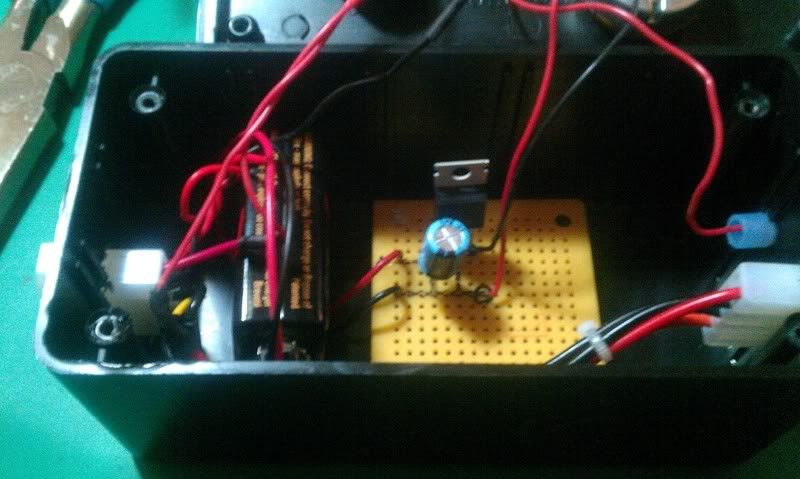

Here are some photo's of the build.

I'm Out for now!

Believe it or not, this actually worked great when I tested it.