- Joined

- Feb 25, 2010

- Messages

- 1,643

- Points

- 113

See this Technical document from Edmonds Scientific:

http://www.edmundoptics.com/optics/prisms/specialty-prisms/anamorphic-prism-pairs/2429

It notes that the output beam will be offset from the input beam by 5.9mm....as I was referring to in an earlier post.

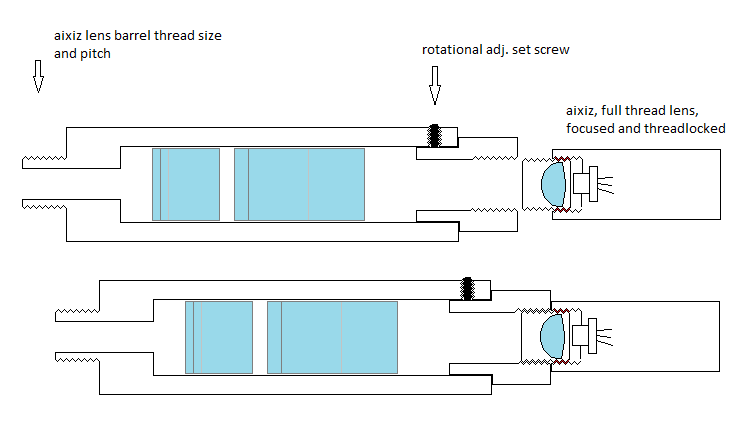

OK....now look at the layout....with a threaded ID....which would accept a typical brass threaded collimation lens barrel....M9 x 0.5 ....the beam path would be centered in that barrel. Project where the beam path will propagate into the first Anamorphic prism.....right on that prism corner. This cannot be.

The beam path MUST strike into the first prism as shown in my drawing attached...APM-AO-V3....then the propagation path will shift and strike the second prism dead centre as shown. The path has a different angle of incidence as it enters the second prism...and travels as shown. This IS what will happen....and this is why ES notes a 5.9mm shift.

OK....so what !! This means that the prism set MUST be shifted to the right....as viewed from a plan view perspective. This then drives the need for the geometry of the small optical platform to be enlarged to accommodate the shifting of the optics.

It would work....just NOT as presented in the Crazyspaz 3D rendering....Close...but a little bigger. It would have a larger diameter front section to provide room for the prism's to be shifted.

Mmmmmmmmm ????:thinking::thinking:

One could take a solid Aluminum rod....say 1" in diameter by 1.5" long. Machine off 1/2 the diameter back 1 1/4". Then...bore a hole in the back to a M9 x 0.5 thread size. This bore would the accept the collimation lens. Maybe add a set screw provision to lock down the lens ??

This then would deliver a miniature optical platform....a flat extension to which the Anamorphic prism's could be secured with epoxy. If you think about...this IS the very same concept that ARG first used with his first 445 dual build....and that I copied/used with the Tridentis and Dragon's Head build....just on a MUCH smaller scale.

Come to think of it....make the OD of your Aluminum rod stock 1.25" !!! In this way....the optical platform would be big enough that the end could be shrouded with a tube of acrylic or metal to entomb the business end ...thereby protecting the optics and making things look more tidy !!!

I will throw together a drawing.....but....this approach IS much more elegant, simple, easier to fab...and therefore less $$$

What is amazing here... is how we springboard of each other's ideas. Synergy...THEN..." Bob's your Uncle " HAHAHAHA

Lite'em Up CDBEAM=======>

http://www.edmundoptics.com/optics/prisms/specialty-prisms/anamorphic-prism-pairs/2429

It notes that the output beam will be offset from the input beam by 5.9mm....as I was referring to in an earlier post.

OK....now look at the layout....with a threaded ID....which would accept a typical brass threaded collimation lens barrel....M9 x 0.5 ....the beam path would be centered in that barrel. Project where the beam path will propagate into the first Anamorphic prism.....right on that prism corner. This cannot be.

The beam path MUST strike into the first prism as shown in my drawing attached...APM-AO-V3....then the propagation path will shift and strike the second prism dead centre as shown. The path has a different angle of incidence as it enters the second prism...and travels as shown. This IS what will happen....and this is why ES notes a 5.9mm shift.

OK....so what !! This means that the prism set MUST be shifted to the right....as viewed from a plan view perspective. This then drives the need for the geometry of the small optical platform to be enlarged to accommodate the shifting of the optics.

It would work....just NOT as presented in the Crazyspaz 3D rendering....Close...but a little bigger. It would have a larger diameter front section to provide room for the prism's to be shifted.

Mmmmmmmmm ????:thinking::thinking:

One could take a solid Aluminum rod....say 1" in diameter by 1.5" long. Machine off 1/2 the diameter back 1 1/4". Then...bore a hole in the back to a M9 x 0.5 thread size. This bore would the accept the collimation lens. Maybe add a set screw provision to lock down the lens ??

This then would deliver a miniature optical platform....a flat extension to which the Anamorphic prism's could be secured with epoxy. If you think about...this IS the very same concept that ARG first used with his first 445 dual build....and that I copied/used with the Tridentis and Dragon's Head build....just on a MUCH smaller scale.

Come to think of it....make the OD of your Aluminum rod stock 1.25" !!! In this way....the optical platform would be big enough that the end could be shrouded with a tube of acrylic or metal to entomb the business end ...thereby protecting the optics and making things look more tidy !!!

I will throw together a drawing.....but....this approach IS much more elegant, simple, easier to fab...and therefore less $$$

What is amazing here... is how we springboard of each other's ideas. Synergy...THEN..." Bob's your Uncle " HAHAHAHA

Lite'em Up CDBEAM=======>

Attachments

Last edited: