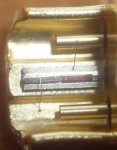

i just bought another 112D drive to harvest, i opened it up, desoldered the ribbon strip and shorted it with solder, i then pushed the diode out of the heatsink with a pair of plyers, pushing on the edges of the front of the diode. i put it in a module and tested it with an lm317 circuit with pre set 100mA current (still with the ribbon cable attached, haven't touched it with a soldering iron.)

nothing but dull red-orange light coming out... and it was only drawing 40mA with ~5V accross the diode.

WTF?!?!???

ANOTHER $40 WASTED!

and i have no idea why

I didn't even get a glimmer of laser light out of this one :'(

nothing but dull red-orange light coming out... and it was only drawing 40mA with ~5V accross the diode.

WTF?!?!???

ANOTHER $40 WASTED!

and i have no idea why

I didn't even get a glimmer of laser light out of this one :'(