laser marshal

New member

- Joined

- Aug 31, 2019

- Messages

- 26

- Points

- 3

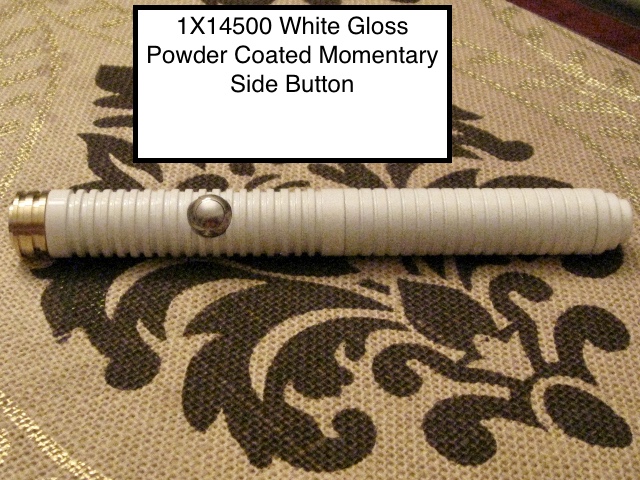

I have just finished seeing the collection of this member's laser host from the Lifetime17

And what struck me and liked me was precisely that "black powder" what is its power?

The procedure used to give it the opaque black color is to spray it with black powder with a compressed air sprayer

And then put it in the oven at 450 ° ?

And what struck me and liked me was precisely that "black powder" what is its power?

The procedure used to give it the opaque black color is to spray it with black powder with a compressed air sprayer

And then put it in the oven at 450 ° ?