I just recently ordered and received this 445nm diode premounted to a module from one of the forum sellers... and it appears to be pressed in ever so slightly crooked.

I have allready contacted the seller and while he's provided me with very good service, and offered that I could send it back and have it fixed by him, I really don't want to go through that trouble if I don't need to. We're talking about a very, very small angle here.

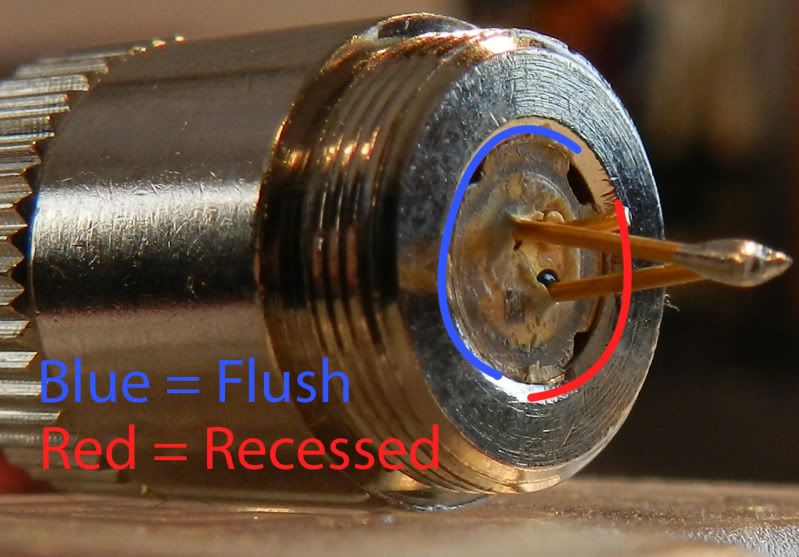

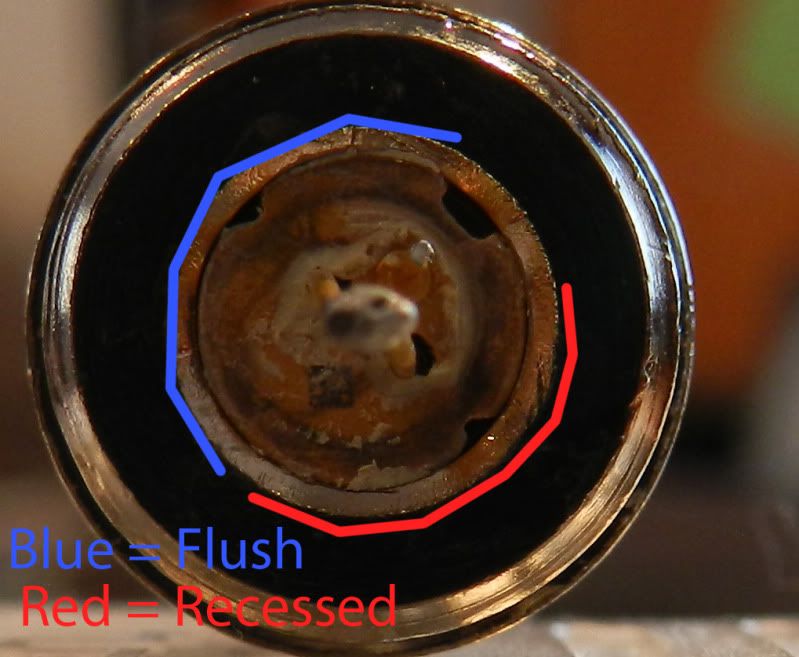

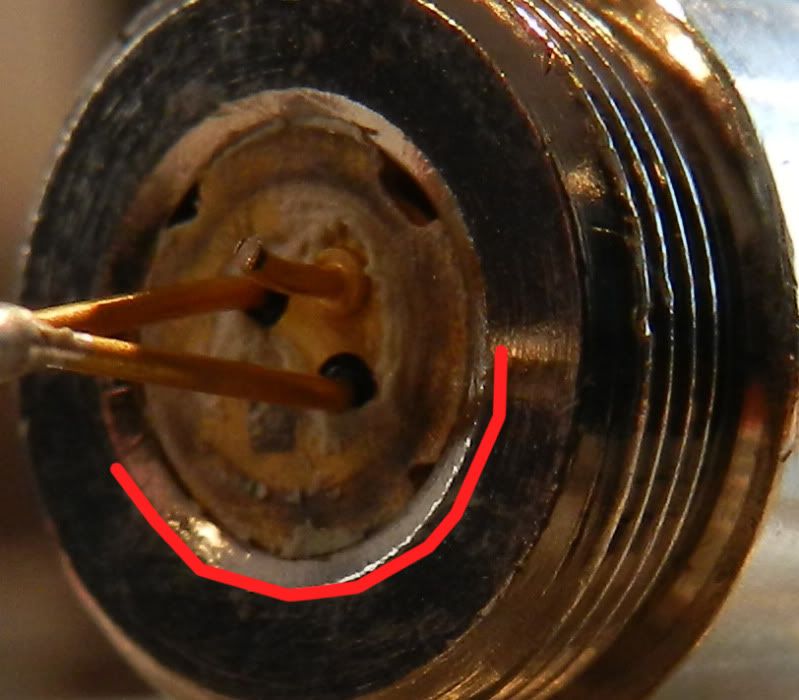

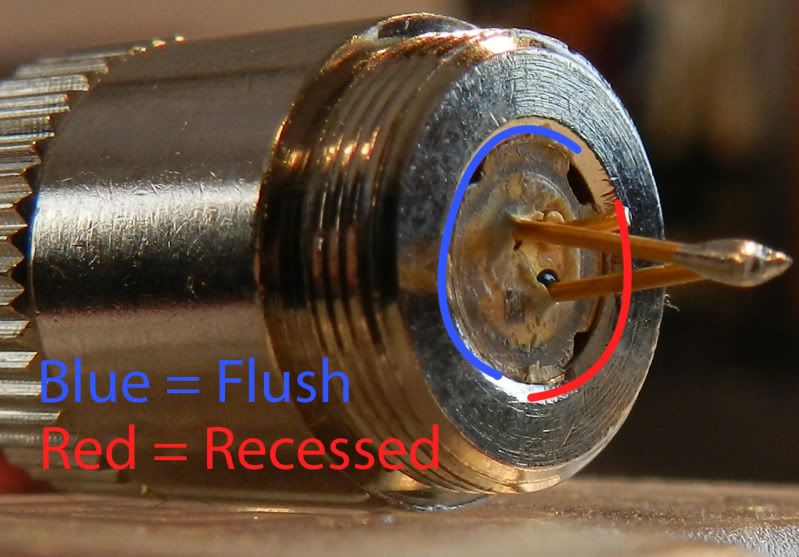

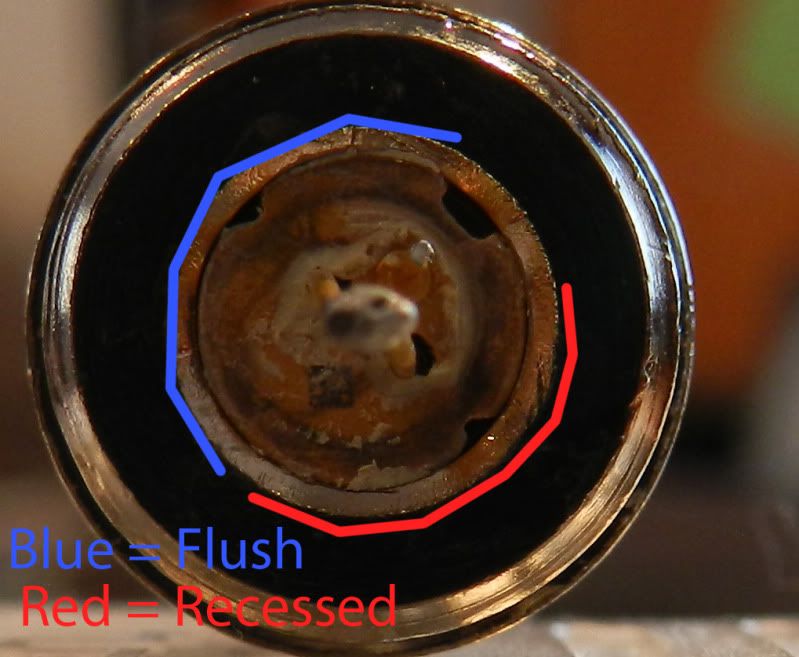

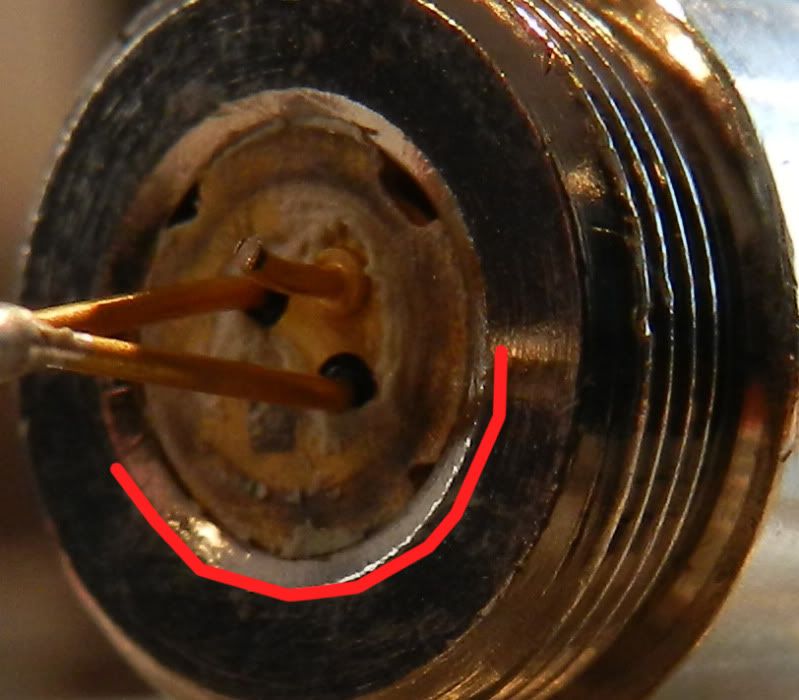

I have done my best to take a few pictures that show the alignment, highlighted in blue is where the diode meets the angled wall of the module perfectly; whilst the part highlighted in red sits just a bit deeper, equivalent to the thickness of about 4-5 sheets of regular weight printer paper... (lack of a better tool for measuring such a small gap)

I was wondering if anyone here ever had the same issues, and if so, did it impact the final product; what are your recommendations; or does anyone have a DIY simili press-a-magig trick to suggest ?

I have allready contacted the seller and while he's provided me with very good service, and offered that I could send it back and have it fixed by him, I really don't want to go through that trouble if I don't need to. We're talking about a very, very small angle here.

I have done my best to take a few pictures that show the alignment, highlighted in blue is where the diode meets the angled wall of the module perfectly; whilst the part highlighted in red sits just a bit deeper, equivalent to the thickness of about 4-5 sheets of regular weight printer paper... (lack of a better tool for measuring such a small gap)

I was wondering if anyone here ever had the same issues, and if so, did it impact the final product; what are your recommendations; or does anyone have a DIY simili press-a-magig trick to suggest ?