Hello!

I need help with building not very powerful laser engraving module for a small scale home grade stuff, for example - burning away thin coating of paint from metal for chemical etching, burning pictures on wood, etc.

My plan is to buy a PLTB450B or M140, so i wanted to know is there a significant difference in this diodes for my application, and which one may be better suited for it?

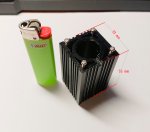

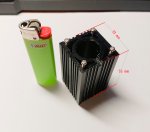

But the core of my questions is about cooling the laser diode, because i want to achieve a continuous operation time of maybe 20-30 minutes (the more the better). As a heatsink/host for the diode i want to use a heatsink from a "500 mw" chinese laser module, which hosted a blu-ray diode (3.6 mm).

This heatsink/host comes in two parts:

1) Black anodized aluminium body with 18mm in diameter hole and a small fan mounted on top (not shown).

2) Aluminium laser host 18mm in diameter with focusing lens and a hole enlarged to accept 5.6mm diode

When the diode is installed it screws pretty tight.

So my question is: Will this setup be able to successfully transfer heat away from PLTB450B or M140 and provide long continuous operation, given the laser diode's current is set to value recommended by it's datasheet? Also, will this lens be capable to focus the beam efficiently?

Alternative variant is to buy this host on ebay and fit it into original black body, will this setup work? Will it be able to efficiently focus the beam?

If not, what heatsink/host can you recommend?

Thank you all in advance!

I need help with building not very powerful laser engraving module for a small scale home grade stuff, for example - burning away thin coating of paint from metal for chemical etching, burning pictures on wood, etc.

My plan is to buy a PLTB450B or M140, so i wanted to know is there a significant difference in this diodes for my application, and which one may be better suited for it?

But the core of my questions is about cooling the laser diode, because i want to achieve a continuous operation time of maybe 20-30 minutes (the more the better). As a heatsink/host for the diode i want to use a heatsink from a "500 mw" chinese laser module, which hosted a blu-ray diode (3.6 mm).

This heatsink/host comes in two parts:

1) Black anodized aluminium body with 18mm in diameter hole and a small fan mounted on top (not shown).

2) Aluminium laser host 18mm in diameter with focusing lens and a hole enlarged to accept 5.6mm diode

When the diode is installed it screws pretty tight.

So my question is: Will this setup be able to successfully transfer heat away from PLTB450B or M140 and provide long continuous operation, given the laser diode's current is set to value recommended by it's datasheet? Also, will this lens be capable to focus the beam efficiently?

Alternative variant is to buy this host on ebay and fit it into original black body, will this setup work? Will it be able to efficiently focus the beam?

If not, what heatsink/host can you recommend?

Thank you all in advance!