- Joined

- Nov 1, 2014

- Messages

- 662

- Points

- 28

I have been searching through the forums for some microprocessor switch with some safety features and I happen to see Everett's lasr lock system. That system is similar to Wicked Lasers Smart Switch where a code is required to switch the laser on. I was talking to him on BLF about it and he is willing to make the code open source. Instead of posting the link to the source code in the thread, I will be making a new thread for it. All credits belongs to Everett.

---------------------------------------

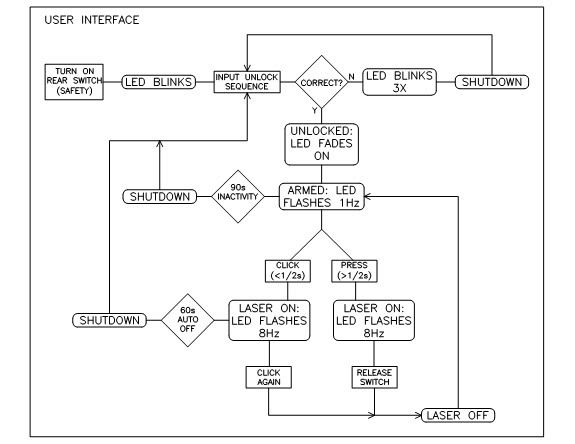

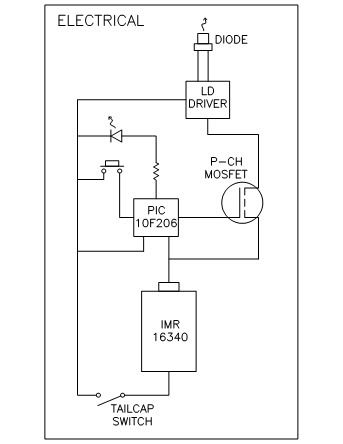

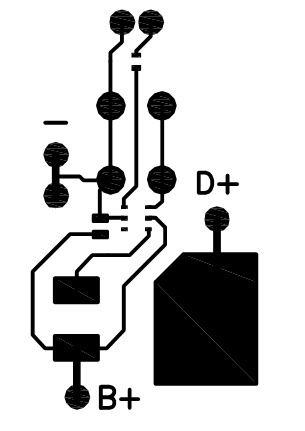

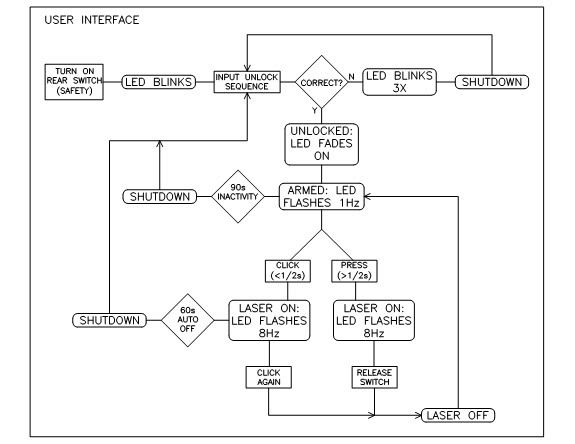

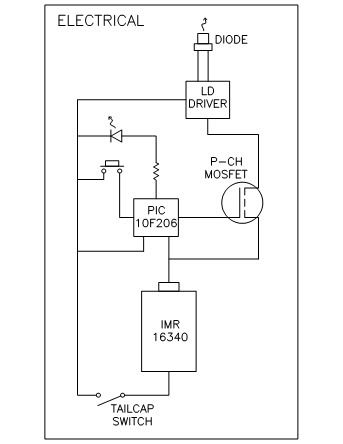

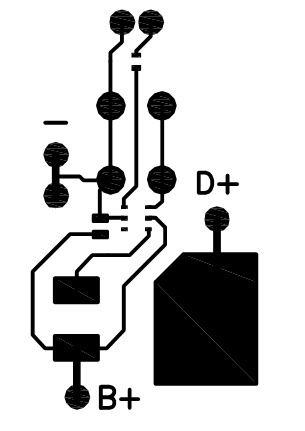

The Laser Lock system would increase the safety of the device. The system uses a PIC 10F206 microcontroller and 4 other components to create a system that controls whether the laser driver gets power from the battery. The tailcap switch now forms a safety switch, and a side clicky (momentary switch) and an LED is used to interact with the Laser Lock. Laser Lock requires an access code based on a short series of presses and clicks in order to arm the laser. It uses the LED to give the user feedback, indicating the events: safety off, incorrect code, unlocking, armed, and firing. The system also implements a momentary and a constant mode, and an automatic shutdown in constant mode. Here's a video that goes over the operation. Below are all Everett's documentation of the system as well as a design for a PCB that can be made at home using the toner transfer method.

The code for the system can be found here. It is written in PIC assembly and fairly well commented. The whole code is about 260 instructions only.

---------------------------------------

The Laser Lock system would increase the safety of the device. The system uses a PIC 10F206 microcontroller and 4 other components to create a system that controls whether the laser driver gets power from the battery. The tailcap switch now forms a safety switch, and a side clicky (momentary switch) and an LED is used to interact with the Laser Lock. Laser Lock requires an access code based on a short series of presses and clicks in order to arm the laser. It uses the LED to give the user feedback, indicating the events: safety off, incorrect code, unlocking, armed, and firing. The system also implements a momentary and a constant mode, and an automatic shutdown in constant mode. Here's a video that goes over the operation. Below are all Everett's documentation of the system as well as a design for a PCB that can be made at home using the toner transfer method.

The code for the system can be found here. It is written in PIC assembly and fairly well commented. The whole code is about 260 instructions only.

Last edited: