- Joined

- Nov 4, 2014

- Messages

- 1,146

- Points

- 63

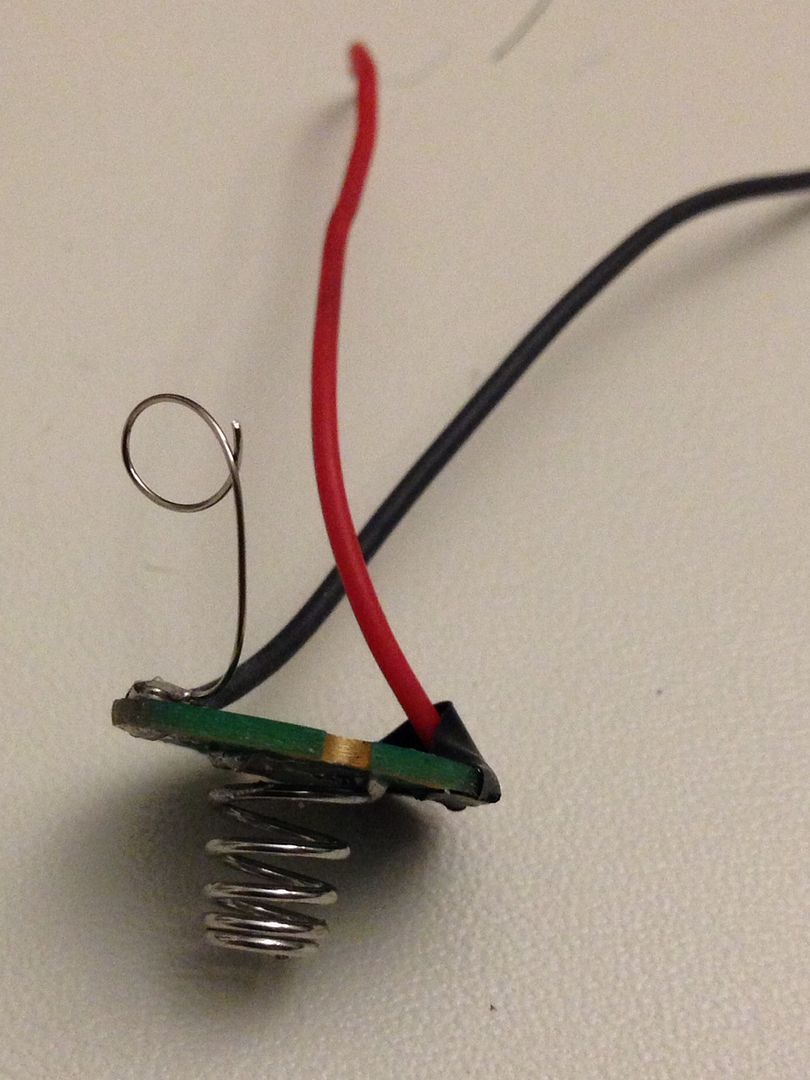

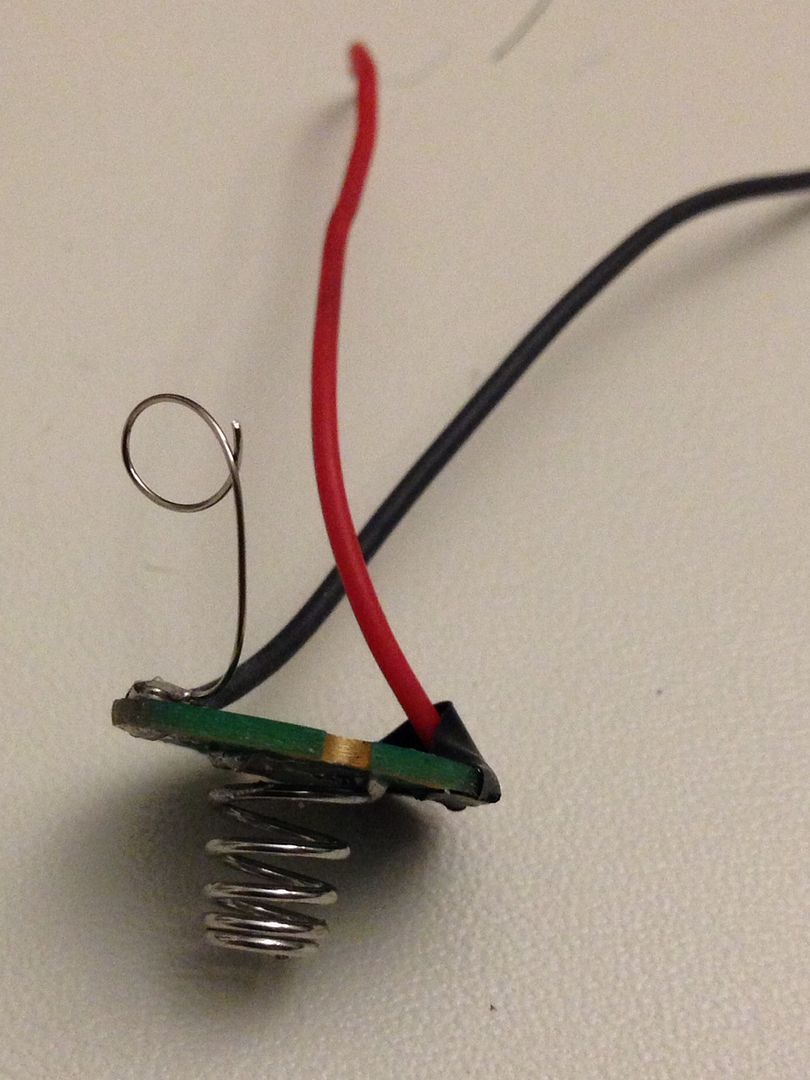

I'm building a M462 into a Kryton. I came up with this and need to know if there is a problem with my idea. I soldered a spring to the neg lead at the contact boards to make contact with the host. The spring is stiff enough to ensure good pressure and solid contact. I made sure the anodizing is sanded off inside the host. So my plan is to connect the pos and neg leads to the driver.

I installed a battery and connected the contact board leads to a hobby motor using this spring idea and the motor ran fine.

Am I good to go?

I installed a battery and connected the contact board leads to a hobby motor using this spring idea and the motor ran fine.

Am I good to go?

Last edited: