Pman

0

- Joined

- Nov 28, 2012

- Messages

- 4,441

- Points

- 113

So here's another 07E build that I put together that I will include some simple build steps for that are not in depth.

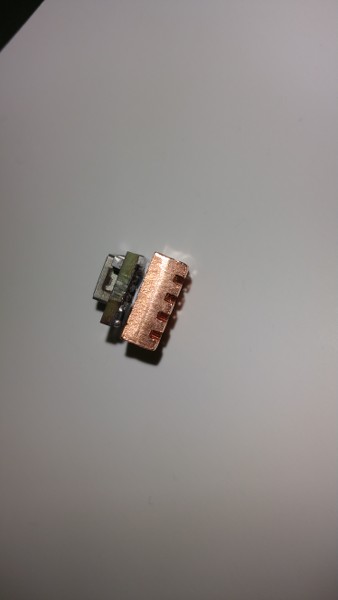

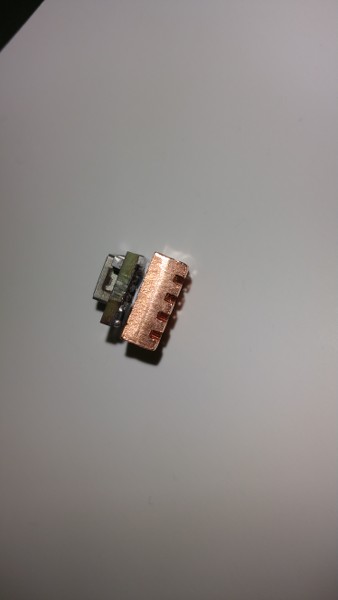

Here's the SXD-V3 driver heat sinked with a thick chunk of copper. The actual Arctic Alumina adhesive is very thin between the 5A driver and the sink but there's extra to make sure they are really stuck together as the sink weighs way more then the driver:

Diode is pressed into the copper module with a full back half and I will say I did not enjoy having to remove the g-ball/can:

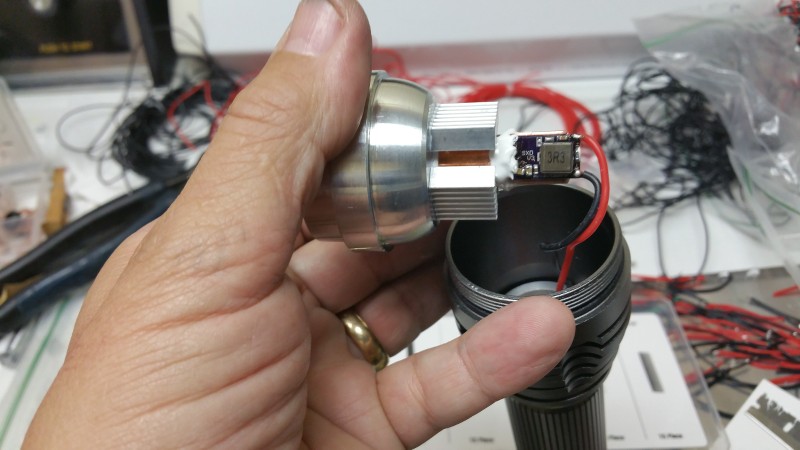

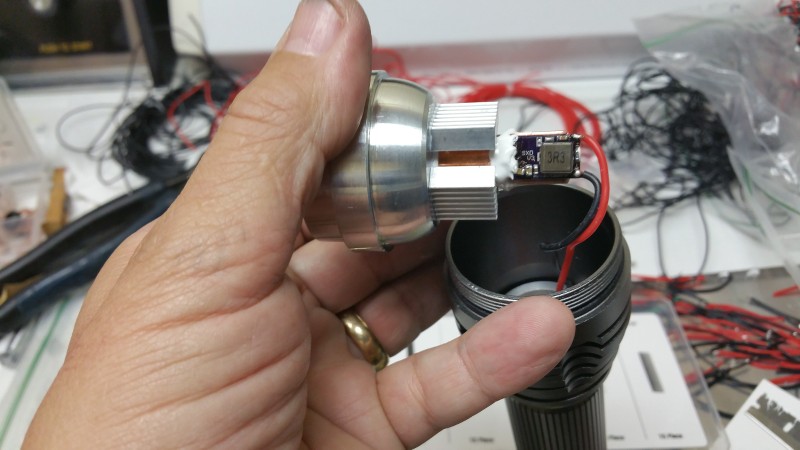

I pressed it into the heat-sink with thermal grease and then used Arctic Alumina again for 2 things. I used it to attach another full back half of copper and to make sure the module didn't move because something was wrong at the end of the sink as the threads would not allow the set screw to screw in to hold the module in place. I trimmed down the lip on the one side before I wired the diode to the driver:

All wired up and you can see in these pics that I added extra sinks that touch both the back half of the main aluminum sink and also the extra copper back half as there was lots of room left in the host:

Finished laser labeled. Should be about 471nm. 5W+

Here's a rarity. A Pman laser outside:

Lots of light out still but there's the beam:

Slightly darker:

Darker still:

Sun is basically down. See how the real color is starting to show now:

Neighbors roof:

I'll be adding shots with my other 2 07E to compare so I'm saving the second post slot.

Here's the SXD-V3 driver heat sinked with a thick chunk of copper. The actual Arctic Alumina adhesive is very thin between the 5A driver and the sink but there's extra to make sure they are really stuck together as the sink weighs way more then the driver:

Diode is pressed into the copper module with a full back half and I will say I did not enjoy having to remove the g-ball/can:

I pressed it into the heat-sink with thermal grease and then used Arctic Alumina again for 2 things. I used it to attach another full back half of copper and to make sure the module didn't move because something was wrong at the end of the sink as the threads would not allow the set screw to screw in to hold the module in place. I trimmed down the lip on the one side before I wired the diode to the driver:

All wired up and you can see in these pics that I added extra sinks that touch both the back half of the main aluminum sink and also the extra copper back half as there was lots of room left in the host:

Finished laser labeled. Should be about 471nm. 5W+

Here's a rarity. A Pman laser outside:

Lots of light out still but there's the beam:

Slightly darker:

Darker still:

Sun is basically down. See how the real color is starting to show now:

Neighbors roof:

I'll be adding shots with my other 2 07E to compare so I'm saving the second post slot.

Last edited: