LOL, that was for sell an LPM

I mean something similar (check for grammatical massacres, i'm not English

)

**********

Well, cause there was around some different informations about LPMs usage, i decided to join some of the posts i made in the past in a generical explanation about different LPMs and head systems, and about how to use (and NOT use

) them.

(and no, you can't pass your test with a "TL;DR" reply

)

OK, seriously ..... the first dinstinction to do, about LPMs, is based on the technology used in their reading heads, cause, basically, regardless the fact that you have a digital or analog or mixed type instrument, or that it do datalogging or not, or that it just measure Watt or Watt and Joule, the main function of a similar instrument is always to give you an indication about the optical power of your lasers, so it's not important what instrument you have, but how you must use it, and this depends mainly from the reading head type.

Basically, you can meet few different types of reading heads, so let see them .

First type of reading heads. still used and mainly used for low powers, are the photodiode heads (mostly silicon photodiodes with large sensitive areas, sometimes used with a diffuser, but more commonly as direct reading surface) ..... these types of reading heads have advantages and disadvantages (as any other units), and specifically:

advantages, as lowest readable powers in picowatt ranges (some models can discriminate 10pW), and reaction times discretely fast, compared with other types of sensors, and also they are less sensitive to air flows that can change their temperatures .....

disadvantages, are the max power that you can directly read is around 2W (last professional high cost models reached 3W) the reduced bandwidth (old photodiodes was sensitive only from 400nm to 1100nm, new types and "blue improved" types can actually read from 200nm to 1800nm, but at high costs), also they are

not linears, this means that their readings depend from the wavelenght of the measured laser ..... a natural sensibility curve for a silicon photodiode have a maximum peak around 800nm, and decline almost linearly (a slight curve), in both the directions, til 400nm and til 1100nm) ..... this sensitivity curve can be compensated in two ways: for the more sensitive units that must measure low powers, with a "correction chart", where knowing the wavelenght of the laser that you are measuring, you can multiply the reading for a "correction factor" for each different wavelenght, or with a special dichroic filter that have a transmission curve that is exactly the opposite of the spectral response of the photodiode, so the final output become "almost linear" for a wide range of wavelenghts (this, ofcourse,

reduces the sensitivity of the photodiode to the minimum one, means, to the one that the photodiode have at the wavelenght that gives you the minimum sensitivity) ..... also, photodiodes cannot be used for very short pulsed lasers (nanoseconds range),

and can be ruined more easily than other reading sensors from a too high powered or focused beam (a laser that can ruin a bit the surface of a thermopile, but left it working good, as example, can much more easily completely destroy or shortcut the photodiode)

A second type, more used in a lot of actual devices and from most of the manufacturers (Ophir, Coherent, and so on) is the "Thermopile" array sensor, that is, basically, a thin disk of material with a very high thermal conductivity index (as some ceramics have) where are glued or printed a lot of

thermocouples, all connected in serie ..... this type of detector, opposite of the photodiodes, have less sensitivity (can read from 0.1mW, but not under this limit with precision), but for the opposite is much more robust, both for the power that you can shoot at it (it's called "damage threshold" usually), than mechanically, for the printed types at least ..... also, they can be built for very high powers if needed (150W and over), and, depending from their coating, the sensor can be built specifically for a certain range of wavelenghts, or also "broadband", keeping almost "flat" the response curve, so you don't need to use correction charts ..... they are

slower than photodiodes, in the response time, but using specific materials, coatings and thermal insulations, they can be built also as "absorption" systems, so they can be used as joulemeters also for quick pulsed lasers ..... one of the disadvantages (same as for the TECs types), is that the reading depends from the difference of temperature from the 2 sides of the thermocouples junctions, so

any variation in the temperature of the external body or the disk, due to air flows and air currents, or from radiant heat of any type, change the reading "zero" settings, and this make necessary to check more frequently the correct "zero set" of the LPM for long-time readings.

Another type of sensor is the one based on

Peltier cells TEC devices, used in reverse (Seebeck effect, that is the effect that cause the TECs produces an output voltage proportional to the difference of temperature from the two sides, and from the number of junctions) ..... some manufacturers, like Scientech, have a whole line of reading heads based on these devices (TECs specifically made for this use, not "normal" TECs for cooling), where also, at hobbystic level, this can be a good (and cheap) alternative to high-cost thermopiles units ..... a disadvantage is that, being not specifically built for this use, a normal TEC plate is

less sensitive than a thermopile (still some of them can read til 0.1W, the most part have an 1mW limit), and also it have a longer response time ..... and also a more high

thermal derive for reading cycles that involves prolonged time and high powers (in poor words, it transfer more heat from the reading face to the reference face, making long-time reading a bit more imprecise for high powers, cause the reference face become a bit more hot and the "zero set" point change) ..... also, he spectral response of these cells (except in the case of commercial units, that are certified), depend in large part from the quality and spectral response of the paint that is normally used for coat the reading face ..... not all the so-called "flat black matte" paints are really "flat black" or "matte", in the reality

..... this solution still remain the cheaper one, anyway, at hobby level.

About the coating of thermopiles and TECs, they can be basically two types of coating ..... "surface absorbers" and "volume absorbers" ..... almost all the ones that looks matte black are "surface absorbers" types, where instead when the surface looks made like glass, sometimes black, sometimes gray, they are probably "volume absorbers" ..... the only specific difference is that surface absorbers try to absorb all the possible power being the less reflective possible, the volume absorbers acts like "light traps" inside the coating structure, absorbing the light and converting it in heat in volumetric way ..... both the types, anyway, do basically the same work, also if in different ways, and this work is simply to

convert the more possible part of the incident light in heat ..... for this reason, a reading surface that have some small sign of burning on the borders, can still be used without errors, just avoiding the burned spots (that, having optical characteristics differents from the rest, can cause reading errors) ..... different is when there are large areas of ruined surface, in this case, the head don't worth the effort to be used (about this, if someone want to buy a second-hand reading head, like on ebay, always diffidate from sellers that don't left you see the surface of the reading plate

)

There are other sensor types (photomultipliers, chopped reading sensors, piezo-pyrometers, cryogenic radiometers, trap-tunnel diodes, and so on), but they are so specifics and few used, that is almost unhelpful to mention them here, for our common uses.

About the LPMs themselves, as already said, there is very few substantial differences from them ..... they can have or not datalogging and PC interfaces (and in this case you can use them for plot curves) ..... they can be analog, or digital, or both together ..... they can be pure wattmeters, or have both watt and joule functions ..... but the main and unavoidable function that they

MUST have, is to show you the power read from the reading head, and this is, basically, the only characteristic that is really important, all the rest are optionals "bells and whistles"

(also, for our use, is practically unhelpful to get those that are sold as "energy meter" or "joule meter" and don't have wattmeter function, cause they are mainly designed for pulsed lasers) ..... another thing that they must have is a decent

CALIBRATION, about the effective read value from the head (that, in poor words, means that if the head read "10", they must show you "10", with the minimum possible deviation or tolerance

) ..... calibration is a thing that usually a private cannot do alone, and also a non-specific lab cannot do it with warranty (it's called "traceability", i suppose) ..... also, is not a quick and simple operation, for the instrument itself, cause it involve a lot of factors, including thermal stabilization of the instrument, tolerance checking, repeated cycles, separate calibration for each scale (for the non-MCU units) or curves reprogramming (for the MCU based units), a specific setup that involve a standard reading head as reference, and other, and also, usually, a specific calibration is done "matching" a specific instrument with a specific reading head, and the instrument is considered "calibrated" only if used with that specific head ..... for professional instruments, a yearly calibration must be done at NIST laboratories, documented and made "traceable", where for hobbystic level, sometimes a home-made, non-NIST traceable calibration can be enough

A different thing is Scientech reading heads (at least some of them), that in some series includes inputs on the heads for self-calibration check ..... with these heads, you give to the head a specific stabilized power supply in the calibration input, and can read on the instrument if the reading output is calibrated or not, and in some units, also do a "self calibration" yourself (non NIST grade, but enough for field corrections and checking)

About this, i've seen sometimes peoples complaining cause their home-made LPMs was out calibration of a 2% or similar ..... this is someway funny, considering that the NIST itself consider unavoidable an error between 0.5 and 1% (they call it "expanded uncertainties"

), also with all their instruments and apparates

Now, some words about reading operations, and common precautions to keep, doing them.

First consideration to do: regardless to the type of reading head that you may have, the reading surface of a thermal sensor is

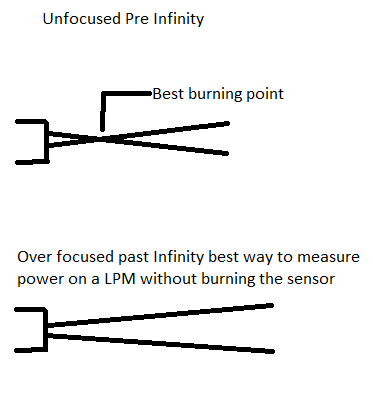

NOT resistant to anything, to infinite abuses ..... one thing is using a 200W thermal head with ceramic plate, another is using a 2W reading head with special ultra-thin plate, or a photodiode head ..... using an

1W FOCUSED to a burning point on one of the sensitive (and delicate) low-power high-resolution plates, can easily end in damaging the surface of it, that, considering the usual cost of thermopiles, is not exactly a funny thing, and in the case of a photodiode, simply destroy it, that is also worse (a thermopile with a damaged surface can still be used, avoiding the damaged point, where instead a short-circuited photodiode can only be throwed away

) ..... so, as fundamental principle,

NEVER EVER read focused beams, nor point them focused for burn to any type of reading heads (except if you are rich enough that you can throw away a reading head each time you measure a laser .....

) ..... this is the first and main principle to follow, all the times, using an LPM.

Second: Always try to use a reading head that is "coherent" with the power of the laser that you are measuring ..... don't use, ofcourse, a 50 or 100 W unit for try to measure your 5mW pointer, and at the same time, don't use your 1W max expensive sensor for check a 5W unit or similar ..... always check first ..... and, if the power of the laser is totally unknown, and you suspect that it can be higher than the maximum power of your reading head, always try it first with the more robust and high power one, or at least, if you don't have multiple units, get somewhere a ND1 filter (a neutral grey 10%-pass filter), and place it in front of your reading sensor for the first trial, especially if your reading head is a photodiode sensor.

Third: if you want to just check a value "on-the-fly", a labby setup is not required, but if you want to made repetitive readings for a review or for plot a graph, or you need some precision, there are some

basical rules to observe in setting up your reading ambient ..... always check that the reading head is repaired from air currents and from any thermal radiant source (this may include power supplies drivers, the LPM itself, or any other instrument that can heat) ..... always keep the reading head insulated from metallic surfaces that can change its own temperature during the reading cycle (most of the commercial heads have a screw hole for fit them on a stand arm or a tripod, but also in case of homemade heads, a layer or two of thick cardboard under the reading head is a very good substitute) ..... for long-time reading cycles, always provide a stand or holder for the laser itself, so the beam can hit the reading face in the same part (will be discussed also this, cause different sensors have different reading characteristics), and also,

do frequent checking of "zero-set" on the LPM, and repeat the cycle at least 2 times, 3 is better, so you can be sure that your reading is effective and the more precise possible.

Fourth: for high power lasers (and i mean, for safety reason, anything over 50mW), always check that the beam, also if the laser under measure become moved, don't hit any reflective surfaces, and i don't mean just mirrors ..... any flat glossy surface can easily reflect enough part of a beam and cause danger, is not necessary that this is a mirror or a glass surface, for do this, especially with some very high powered portable units ..... so, always something that block the beam if it become shifted from the reading head ..... if available, light shields ..... and

safety goggles for the wavelenghts that you are using ..... who said "better safe than sorry" ?

Finally, remember that your reading head is, basically, a

CALORIMETER, and that "read" not just the beam power, but also any other heat radiation that you throw in it ..... an halogen lamp, the heat generated from your laser module, the heat of your hands and body, if the head is sensitive enough, all these things can false your readings, giving you a higher reading respect the real power ..... so, as basical guidelines, always try to keep the laser body at least 15 / 20 cm away from the reading head (more is better), always try to not breath on the reading element, repair it from high intensity light or direct sunlight, and overall,

always avoid to keep the reading head in hand (if not with apposite handlers), cause your body heat will change the "cold" side temperature, falsing the reading.

The better system for proceed, if you need long-time or precision reading, is this one: place all the items in a room with

stable temperature, possibly without air currents (this includes fans, heaters or air-conditioning units), with the reading head insulated from metallic surfaces ..... turn on your LPM and

left it at least 30 minutes for thermal stabilization ..... place your laser on a stand or holder,

at least 20cm or more of distance from the reading head, and

ENSURE THAT THE BEAM IS DEFOCUSED (the better system is to have the beam covering from 50 to 90 % of the surface of the reading head, whatever is possible) before point it to the reading surface, then position the stand or holder in the way that the beam is

MORE CENTERED AS POSSIBLE on the reading surface, and more perpendicular possible to it, turn it off, wait a pair of minutes, then zero-set your LPM ..... wait again a pair of minutes, for be sure that you don't need to refine the zero-setting, then turn on the laser and make your reading cycle ..... turn off the laser, wait a pair of minutes, and note if your zero-setting is changed in the measurement cycle ..... if yes, redo the cycle for at least another pair of times (zero-set, wait, measure, check), and use the medium value of all the readings for your data (or, in alternative, if you do a measure cycle and then note that the zero-setting is NOT changed from the start to the end, you can use those values as the more stable ones) ..... this, basically, for long, continuous reading cycles, for get "average" and medium values ..... if you need a long measurement session but NOT continuous, like, a lot of short measures one after the other, is enough to check the zero-set between each measure, for have a decent precision the same.

Ofcourse, for just a quick check of the power, you don't need all this, just let stabilize the head, set the zero and take the measure, but if you want precision, you need to do the things with precision.

Anyway, NEVER do the error that some sites shows you all the times, reading lasers ..... NEVER keep the laser itself nearest 15/20 cm from the head, and NEVER place the laser in contact with your reading head, this will simply give you false results, in ANY conditions

A word about the "point the beam in the center of the reading plate" thing ..... structural differences in the way of how the sensors are built, make this thing a need, if you want trustable values, especially using thermopiles (except for photodiodes) ..... there is a phisical difference from a thermopile and a TEC cell, that gives you different results in heat distribution and heat draining from the measuring area, so the point where you target the reading area IS important for a correct reading, other than the reading time .....

In more clear words: the TEC cell have the plates made in ceramic (ok, ok, a special ceramic, but i suppose you don't need the formula ), that is more thick and highly thermally conductive, much more than the thermopile reading plate ..... also, the cells are distributed on all the back surface of the plate ..... from the counterpart, the structure of a TEC cell, also if not used for cooling, is much, much more heat transfering than a thermopile reading plate ..... this made it relatively insensitive about the exact point where you shine your laser, cause all the heat transfered to the plate from the laser, is spreaded really quickly on all the surface, and influence in almost equal mode all the cells (except than shining it on a corner, but also this is someway compensated) ..... so, almost regardless than the fact that you shine the laser exactly on the center or not, the reading is practically the same (some minimal differences are always presents, but are so small that does not influence the reading in a really effective way) ..... at the same point, anyway, the more quick transfer of heat from the reading plate to the "cold" plate, due to the big mass of the junctions, tends to "equalize" slowly the temperatures, falsing the reading in long-cycles readings ..... anyway, this does not have a big influence reading low-powered lasers, only reading high-powered ones, indicatively from over 500mW and up ..... this can be, anyway, minimized using a big or very efficent heatsink on the "cold" plate (a thermal compensation can be helpful, too, for long readings, but is not indispensable at hobby level)

On the other side, a thermopile have a totally different structure, especially the sensitive ones that are able to read very few milliwatts ..... builders had to become to a compromise from sensitivity and dimensions, and this means that the reading plate is, sometimes, extremely thin and delicate, made from special materials for maximize the heat transfer speed and at the same time kept small enough for become influenced from very low powers ..... but, you know, infinites does not exists ..... regardlass from what material you use, there's no materials that have an infinite heat transfer speed ..... and also, for the constructive principle of those sensors, the reading elements are a lot of bimetal thermopiles made with very thin metal plates, connected in serie for increase the reading, and placed all around the circumference of the plate .....

This cause a difference in the reading for different zones of the reading surface ..... cause the heat transfer from one place to the whole plate is not infinite, the thermal resistance of the plate itself, causes a higher reading when you shine the beam on the borders of the plate, where the bimetal junctions are directly posed, and a minor (but more correct) reading, when the beam is shined exactly on the center of the plate, cause in this way the reading is the effective power reading of all the heat, equally transferred to all the bimetal junctions (yes, is not that your laser is more powerful if you shine it on the borders, you are simply doing the reading in the wrong way, doing this) ..... also, calibrations and values on the datasheets are given exclusively for beams directed in the center of the plate, covering almost 50% of it, and perpendicular to it, so if your head is rated, as example, 1mV/mW, this is valid ONLY in the above conditions.

For this reason, for a correct use of a thermopile, is required, usually, that the beam is defocused at least on half of the reading surface, and that it will be directed and kept more centrally possible on the reading plate ..... and this is indicated also for TECs sensors.